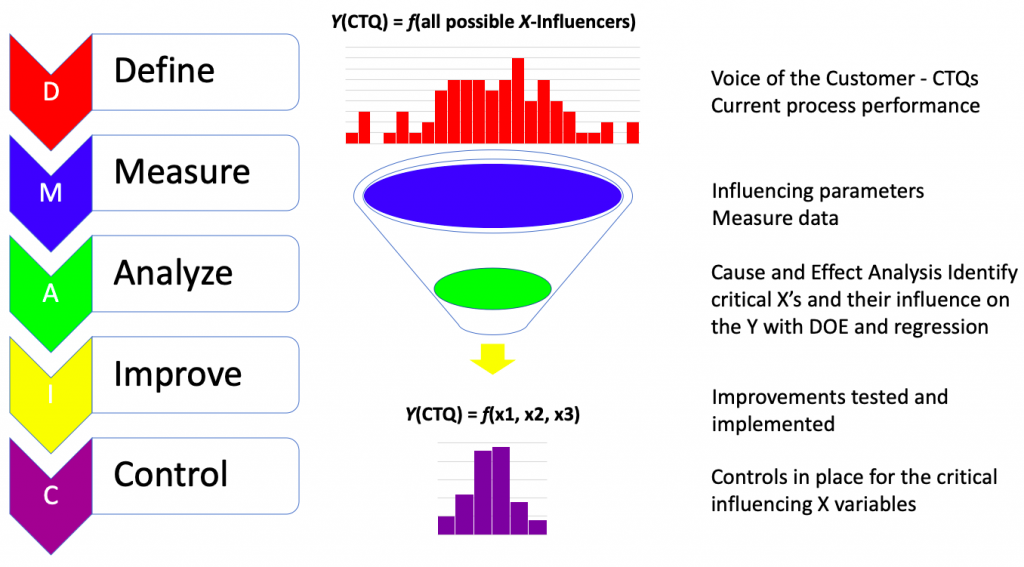

DMAIC should be used when an existing product or process requires improvement to meet or exceed the customer’s requirements. This initiative should be consistent with the business goals of the organization.

Define-Measure-Analyze-Improve-Control

Define

- Customer expectations: VOC and CTQ parameters

- Project goal

- Project team

- Milestones, Budget

- Basic process flow

Measure

- Process mapping

- Sampling plan design

- Measure CTQ parameters – establish process capability.

- Measure influencing parameters

Analyze

- Causal hypotheses

- Key influencing factors for CTQ parameters

- Prioritization of improvement projects

Improve

- Establish a hypothesis to be tested

- Analyze the data for the new process to show that the implemented changes result in an improved process and quantify this improvement.

Control

- Statistical Process Control

- Control Charts

Define

The Define phase is the starting point for all Lean Six Sigma projects. Whether the project will rely more on Lean tools and principles or those from Six Sigma, the deliverables for this phase are the same. Quality must be defined according to what the customer wants regarding measurable characteristics within the limits of their variability.

The first step is to identify a problem. Lean six sigma approach utilizes Y=f(X); the function defines one variable in terms of another. The statement “y is a function of x” (denoted y = y(x)) means that y varies according to whatever value x takes on.

Objective:

- Define the project’s purpose;

- Problem/Opportunity to be solved and scope;

- Background on the process and customer;

- Customer requirements and process.

Key Steps:

- Develop business case;

- Develop project team charter;

- Understand customer requirements and processes.

Output:

- A clear statement of the intended improvement and how it is to be measured;

- A high-level map of the process

- A list of what is essential to the customer and measurable requirements.

Measure

The Measure phase will require developing a deep understanding of what your customer wants from you. The main focus will be on the type of data needed, as well you will need to ensure that you have the correct approach for gathering these data points. During the Measure phase, the team is concerned with creating a baseline for the process and tweaking problem statements and other outputs of the Define stage.

Objective:

- Gather information on the current situation;

- Identify and implement measures to establish baseline performance;

- Quantify the opportunity;

Key Steps:

- Determine what to measure;

- Understand variation;

- Assess the measurement system and process performance.

Output:

- Data that pinpoints problem location or occurrence;

- Baseline data on current process sigma;

- More focused problem statement.

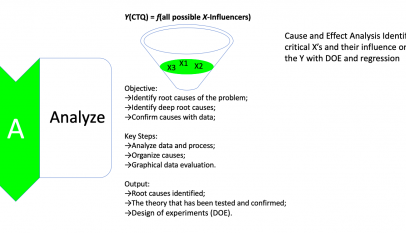

Analyze

We have reached the Analyze phase, the business case for the project has been approved, potential pushback from key stakeholders has been decreased, the process has been mapped, and data from the critical processes have been collected. The main objective of this phase is to use various tools and methods to identify and confirm the root cause of the problem so that later in the Improve phase, we can come up with a reliable fix.

Objective:

- Identify the root causes of the problem;

- Identify deep root causes;

- Confirm causes with data.

Key Steps:

- Analyze data and process;

- Organize causes;

- Graphical data evaluation.

Output:

- Root causes identified;

- The theory that has been tested and confirmed;

- Design of experiments (DOE).

Improve

The Improve phase is focused on selecting the improvement ideas that were either identified by the team or determined through #data analysis. It is also in this phase that the implementation plan is developed.

“The improvement team and the whole workforce should be able to see things changing before their eyes.” – Jones, Daniel T. “Lean Thinking…”

Objective:

- Determine possible solutions that will address the identified root cause(s);

- Implement the preferred solution;

- Confirm that the problem and its root cause(s) have been reduced/eliminated.

Key Steps:

- Generate and access potential solutions;

- Select and test the preferred solution;

- Implement solutions and verify effectiveness.

Output:

- Preferred solution or countermeasures;

- The best solution to eliminate the problem(s) and root cause(s) has been confirmed.

Control

The last phase of Lean Six Sigma is Control. This phase focuses on successfully passing the project to a functional owner and ensuring the long-term sustainability of the improvements.

Objective:

- Prevent the problem from recurring;

- Maintain the gains by documenting, standardizing, and monitoring new processes;

- Develop a control plan – monitoring system.

Key Steps:

- Standardize the solution;

- Implement scorecard;

- Document project.

Output:

- Integrate control charts and control plans;

- Complete documentation of results, lessons learning, and recommendations;

- Solution “embedded” in relevant processes and procedures.

thanks for you sharing on the subject