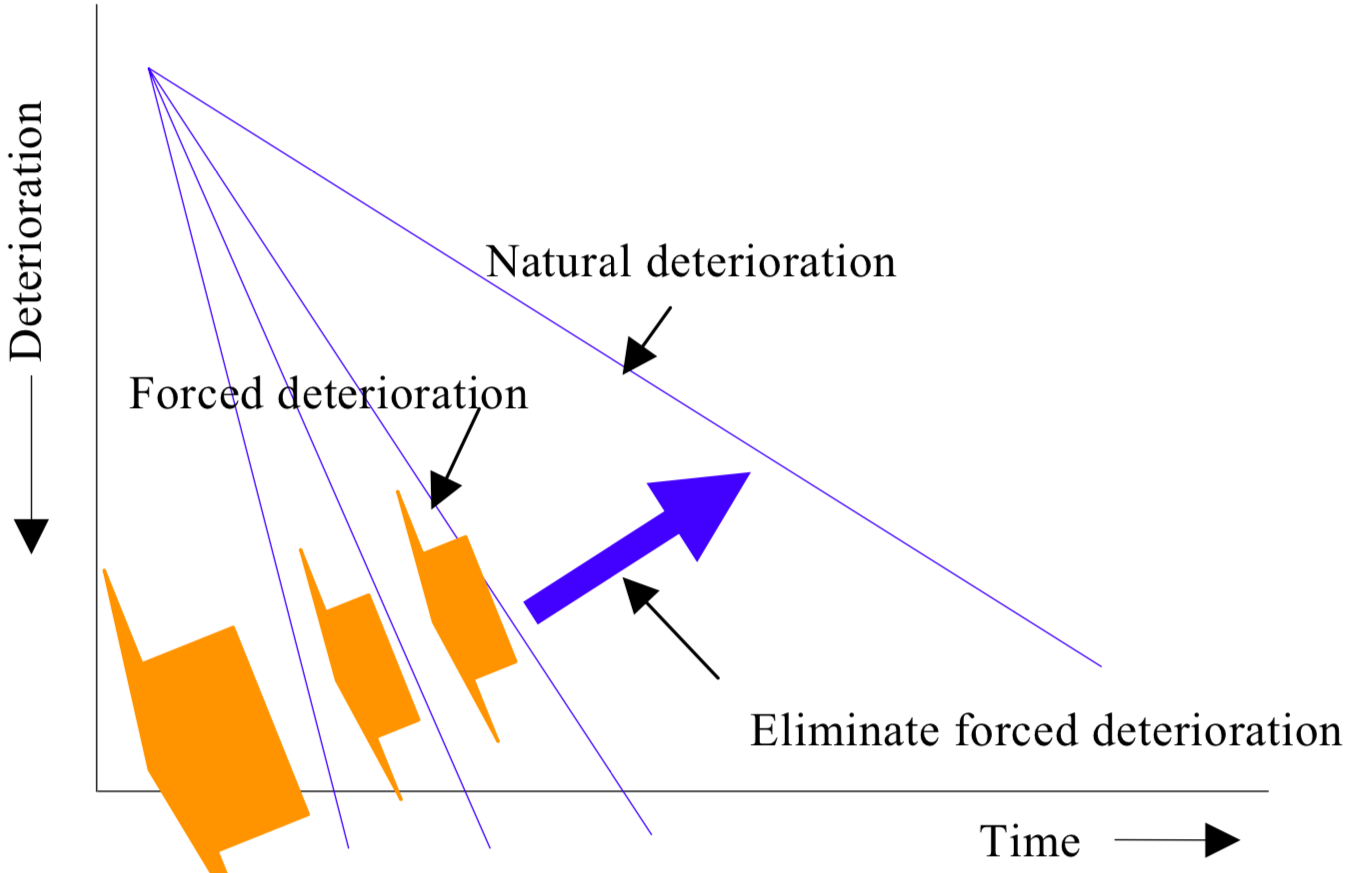

Eliminate Forced Deterioration, to Achieve Stable Equipment Subject to Natural Deterioration Only

Eliminating forced deterioration

Suppose equipment is in a state of forced deterioration. In that case, any attempts to control its precision will be frustrating because the components that determine that accuracy will have short, highly-variable lifetimes, making checking very difficult. The abovementioned makes it essential to eliminate forced deterioration through Autonomous Maintenance, thereby extending and stabilizing component lifetimes.

Ensure that All Staff, from Managers through to Operators, Are Equipment Experts

Developing an equipment-competent workforce

Both managers and the operators who work with machinery must have excellent equipment skills and the ability to sustain the required conditions. To achieve zero defects, production must be carried out in a situation where people and machines are in perfect balance.

For this, operators must be trained to immediately spot any abnormality in the causal system that they think might lead to a defect and know how to deal with that abnormality promptly and accurately.

To ensure that the people in the Operations Department have this level of competence, it is vital to implement Autonomous Maintenance, Focused Improvements, machine diagnosis techniques, skills training, and other related initiatives.

Promoting Quality Maintenance also involves some other important issues:

Activities for achieving zero equipment failures

The most important aspect of Quality Maintenance is eliminating sudden or gradual equipment failures. A particularly constructive approach is identifying the exact correlations between product quality characteristics and equipment conditions (modules and individual components) and then developing and applying diagnostic techniques that expose any deterioration in these conditions.

MP design of new products and new machinery

A system must be established that allows defect-free products and equipment to be created right from the initial design stages. ‘MP design’ (maintenance prevention design) is discussed in the chapter on Early Management.

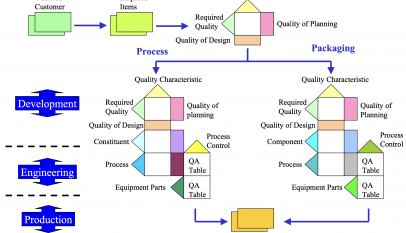

The figure below shows the relationship between Quality Maintenance and the other TPM pillars.