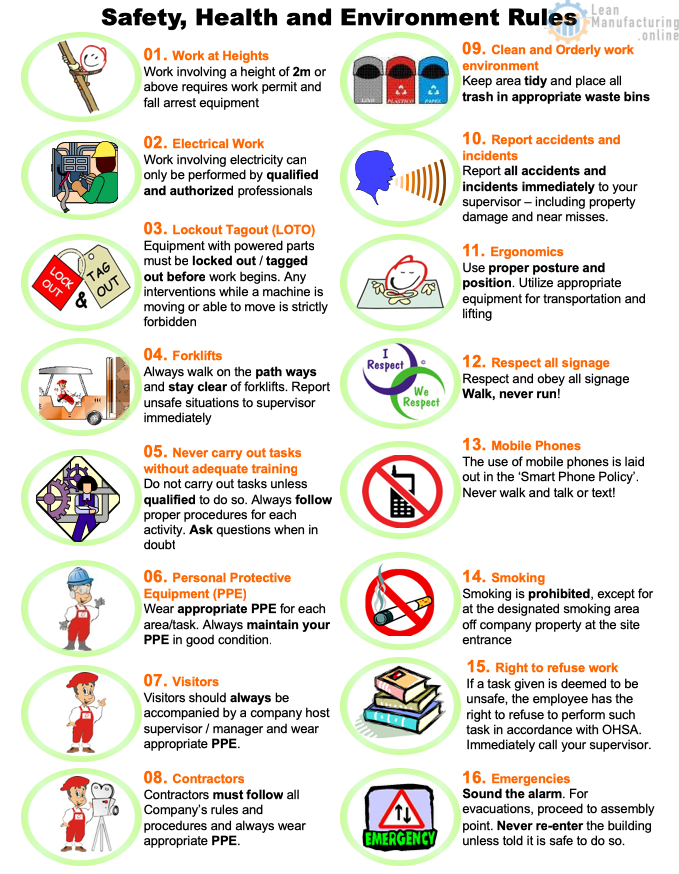

Every manufacturing facility should have a set of SHE rules for workers, visitors/and contractors. Rules must be designed in accordance with company policies as well as local legislation.

Please see below examples of Safety, Health, and Environment Rules:

- Work at Heights

- Work involving a height of 2m or above requires a work permit and fall arrest equipment

- Electrical Work

- Work involving electricity can only be performed by qualified and authorized professionals

- Lockout Tagout (LOTO)

- Equipment with powered parts must be locked out / tagged out before work begins. Any interventions while a machine is moving or able to move is strictly forbidden

- Forklifts

- Always walk on the pathways and stay clear of forklifts. Report unsafe situations to the supervisor immediately

- Never carry out tasks without adequate training

- Do not carry out tasks unless qualified to do so. Always follow proper procedures for each activity. Ask questions when in doubt

- Personal Protective Equipment (PPE)

- Wear appropriate PPE for each area/task. Always maintain your PPE in good condition

- Visitors

- Visitors should always be accompanied by a company host supervisor/manager and wear appropriate PPE

- Contractors

- Contractors must follow all the Company’s rules and procedures and always wear appropriate PPE

- Clean and Orderly work environment

- Keep the area tidy and place all trash in appropriate waste bins

- Report accidents and incidents

- Report all accidents and incidents immediately to your supervisor – including property damage and near misses

- Ergonomics

- Use proper posture and position. Utilize appropriate equipment for transportation and lifting

- Respect all signage

- Respect and obey all signage. Walk, never run!

- Mobile Phones

- The use of mobile phones is laid out in the ‘Smart Phone Policy’. Never walk and talk or text!

- Smoking

- Smoking is prohibited, except in the designated smoking area off company property at the site entrance

- Right to refuse work

- If a task is deemed unsafe, the employee has the right to refuse to perform it under the OHSA. Immediately call your supervisor

- Emergencies

- Sound the alarm. For evacuations, proceed to the assembly point. Never re-enter the building unless told it is safe to do so.

Three Golden Safety Rules

- These three rules are considered the most critical in Manufacturing facilities;

- The rules are designed to protect you and your work colleagues;

- Breaking any of these rules will result in disciplinary action and potentially instant dismissal, or in case of third-party contractors – banning from working at the current location or company-wide.

- Rule 1. Working at heights. It is considered “Work at heights” if the task involves working where your feet are 2 meters or higher above the ground. The standard is stricter (less than 2m) in cases where there is a hazard below the worker’s position, allowing them to fall and potentially hurt themselves. Work at heights must only be carried out by qualified and authorized employees.

- Rule 2. Electrical Work. All electrical work poses a high risk. Electrical work must only be performed by qualified and authorized personnel.

- Rule 3. Lockout/Tagout. For equipment, machines, and installations. Lockout/Tagout ensures that a machine cannot accidentally be energized while work is being performed. Equipment must be locked out/tagged out before any work begins. Any interventions are strictly forbidden while a machine is in motion or is capable of moving.

This training is provided for reference purposes only – always follow the safety rules prescribed by your local legislation and/or Health and Safety (H&S) department.