In this factory, to strengthen 5S sustainability, the 5S standard was located at the right place, close to the workstation.

The 5S Standard is a simple one-page combination of dot points to provide a simple explanation and a photo of “what good looks like”.

After the Team has transformed the area with the first 3Ss, the standard is created to ensure everybody outside the team understands what the “new state” looks like.

This helps maintain the new state and respects the valuable work the team has done in the transformation.

Not only does the 5S standard appear in the right place, but it is also present at the time (right time) that it’s needed the most to ensure everyone knows “what good looks like.”

Template here

Essential Modern Books That Will Expand Your Mind

How to Solve Problems Using PDCA and 5-Why

Mastering Daily Improvement with Toyota Kata: A Practical Guide to Real Results

The Three Pillars of Lean Transformation

How Andon Systems Improve Production Efficiency

Essential Modern Books That Will Expand Your Mind

How to Solve Problems Using PDCA and 5-Why

Mastering Daily Improvement with Toyota Kata: A Practical Guide to Real Results

The Three Pillars of Lean Transformation

How Andon Systems Improve Production Efficiency

5S Audit Checklist and Report

Example of Food Manufacturing site review

TPM 3 Levels – path to World-Class Manufacturing

TPM Pillar Self Assessment

5S standard in the right place at the right time

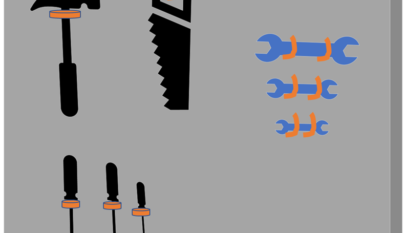

How can Shadow boards improve the efficiency of your process?

5S Audit Checklist and Report

Example of Food Manufacturing site review

TPM 3 Levels – path to World-Class Manufacturing

TPM Pillar Self Assessment

5S standard in the right place at the right time

Most Popular

4M Analysis Process

The purpose of this procedure is to define the steps to do a 4M …