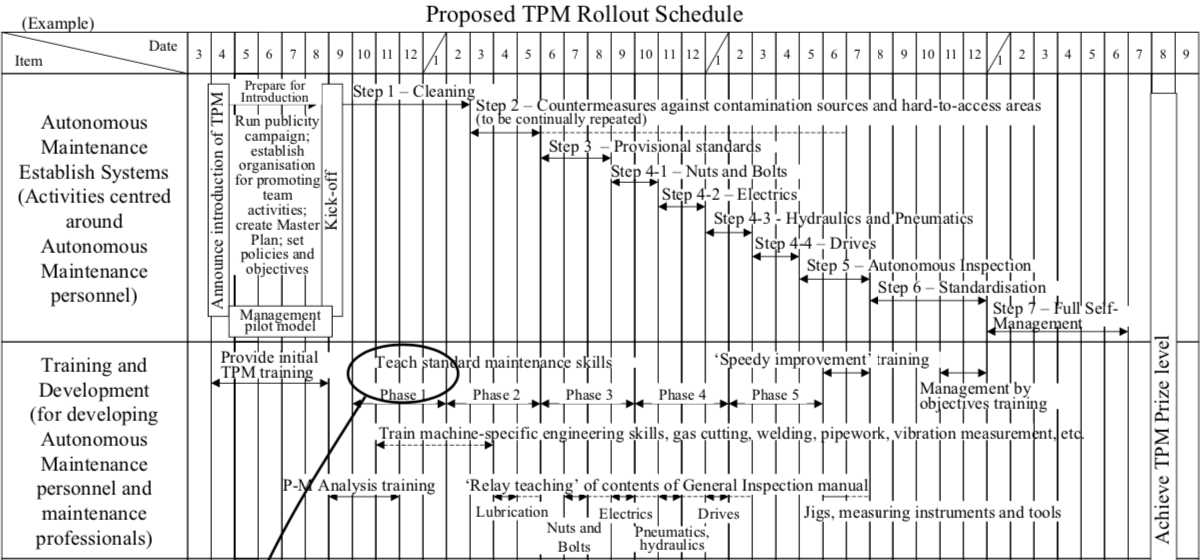

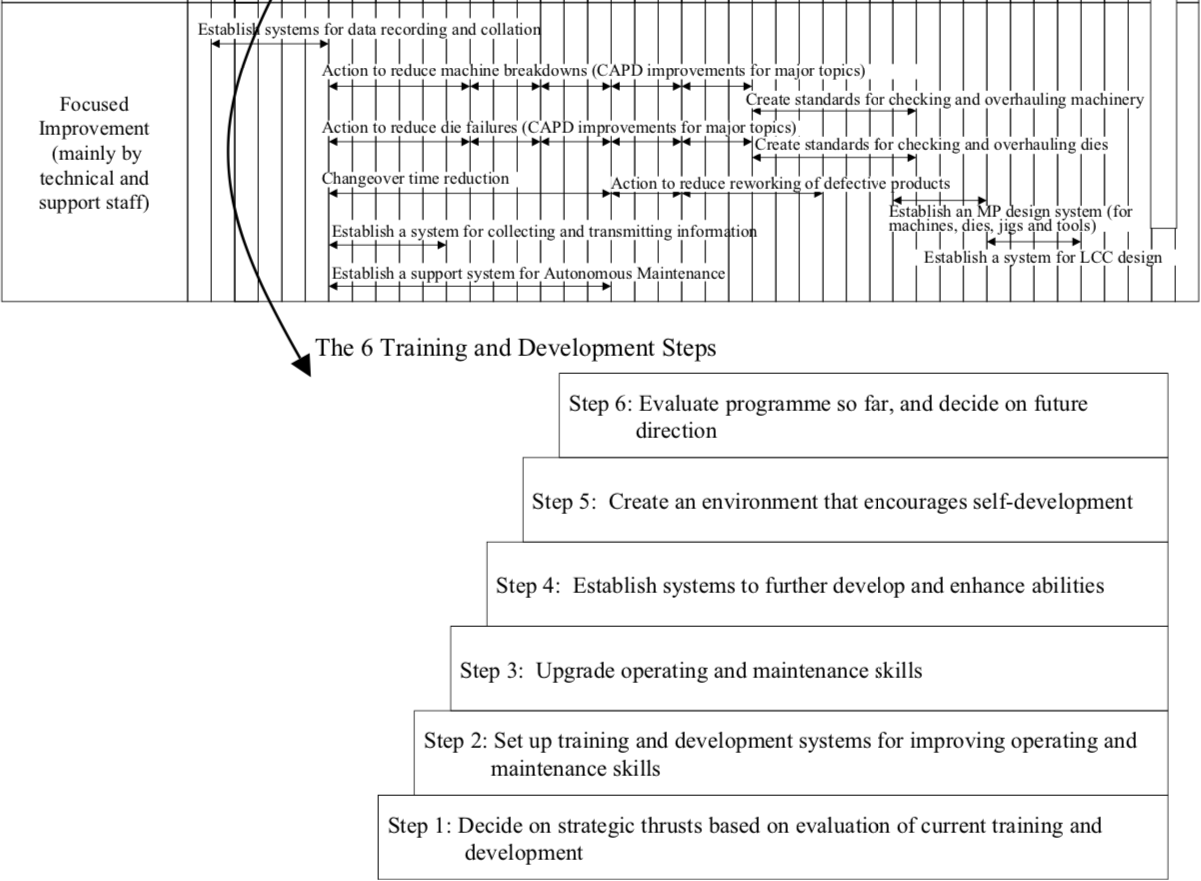

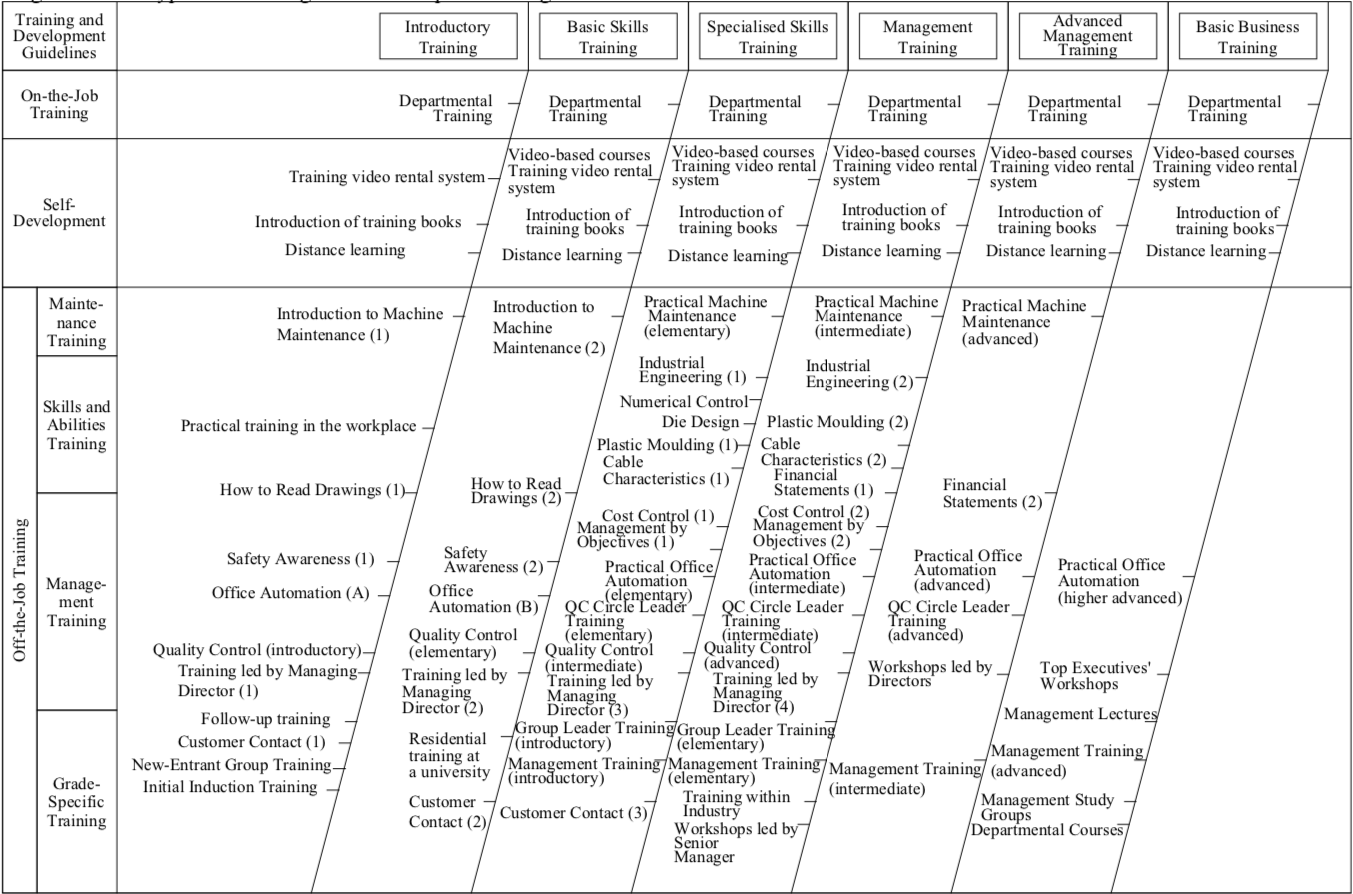

To ensure effective skills improvement, it is recommended that the training and development program be rolled out following the six steps shown in the figure below:

Step 1: Decide on Strategic Thrusts Based on Evaluation of Current Training and Development

Every business carries out training and development in one form or another. However, to become an organization of individuals who fulfill their particular roles highly professionally and know far more about their equipment than their counterparts at rival companies, it is essential to design and implement a training and development program that exactly suits the company’s needs. The first step in doing this is to assess the current situation and work out what the training and development program’s basic policy, goals, and strategic thrusts should be:

An Example of a Training and Development Program’s Basic Policy, Goals, and Strategic Thrusts

Basic Policy

“The basic policy for training and development in our factory is that improving everyone’s individual abilities helps to improve the company’s business results, as well as giving people a sense of pride and achievement in their work and daily lives. We will use on-the-job training and self-development, in conjunction with off-the-job training, to actively raise our levels of expert skills.”

Goals

- Use the TPM program to develop people who are highly competent at handling their equipment and performing administrative tasks.

- Develop people capable of responding to the needs of the workplace over the long term.

Strategic Thrusts

To achieve these goals, we will review our existing training and implement the following strategic thrusts:

- Develop people who understand their equipment extremely well

- Enable maintenance staff to acquire even greater skills and analytical strengths.

- Establish maintenance training curricula, and teach operators to know their equipment intimately.

- Develop specialized skills by sending people on courses run by outside organizations such as the JIPM.

- Develop people who can perform their administrative duties extremely well

- Roll out the Autonomous Maintenance steps and give training in automated office systems.

- Establish skill upgrade programs

- Identify essential core skills to systematically develop people with a high level of competence in handling their equipment and performing administrative tasks.

The next step is to determine what kinds of people and skills the company’s business policies and strategies require, put together training and development plans, and create systems for monitoring progress against those plans and the results achieved.

The human resources and skills a company needs should be examined in the light of the systems and equipment in its factories, its business processes, and the organization and business model by which it operates. It is generally sufficient for people in leadership positions to conduct a review based on this information, and identify the necessary work skills.

Step 2: Set up Training and Development Systems for Improving Operating and Maintenance Skills

Unattended operation is becoming more and more prevalent on the production floor owing to modern advances in robotization, numerical control, and automation. Many firms are endeavoring to hire and train engineers and specialists with strong technical skills and abilities in mechatronics and machinery to cope with this trend, but it is not something that can be done overnight. It is particularly important to have an effective training and development program for giving operators and maintenance personnel at every level a high degree of competence in equipment systems. The kind of program shown in Figure 9.6 should be developed in tandem with the company’s equipment environment as part of its overall training and development system.

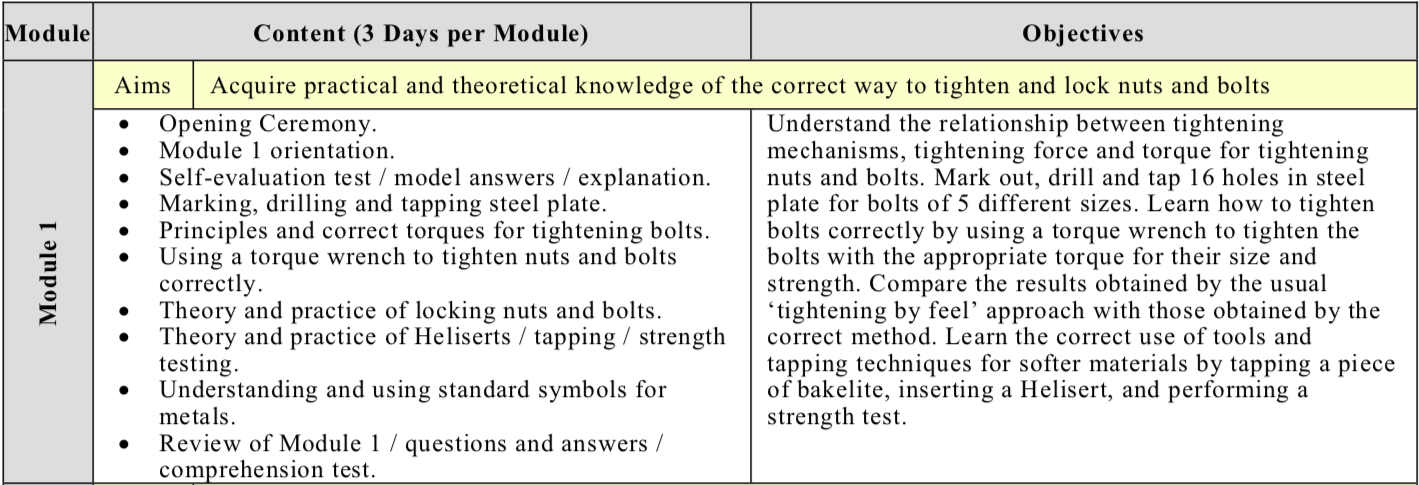

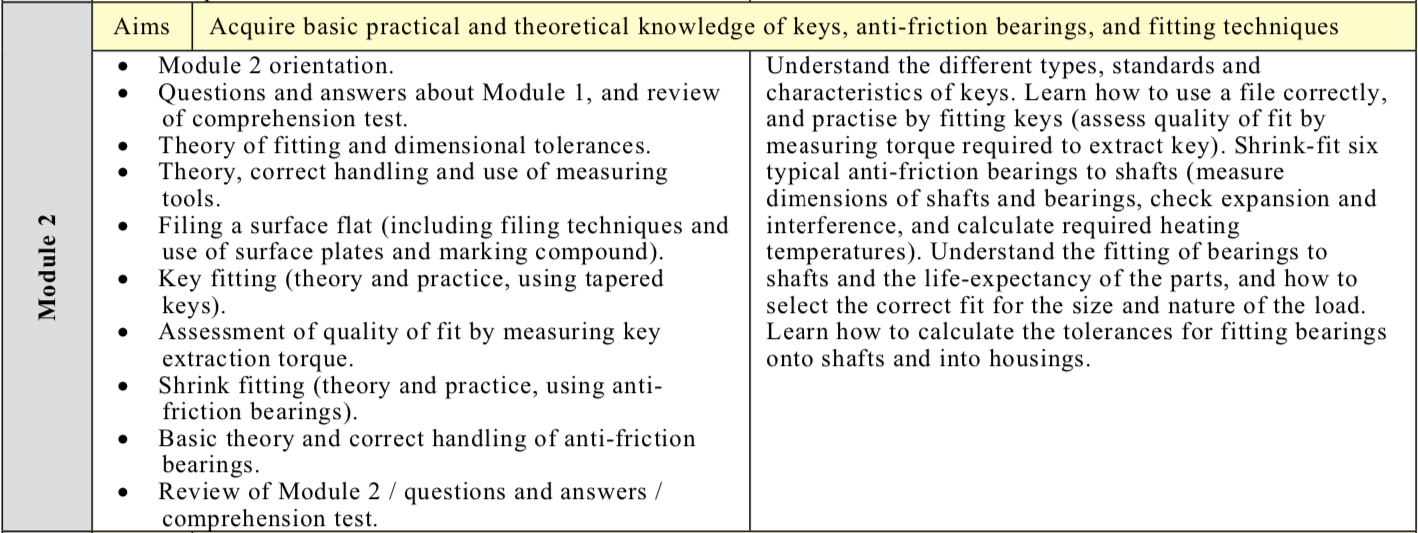

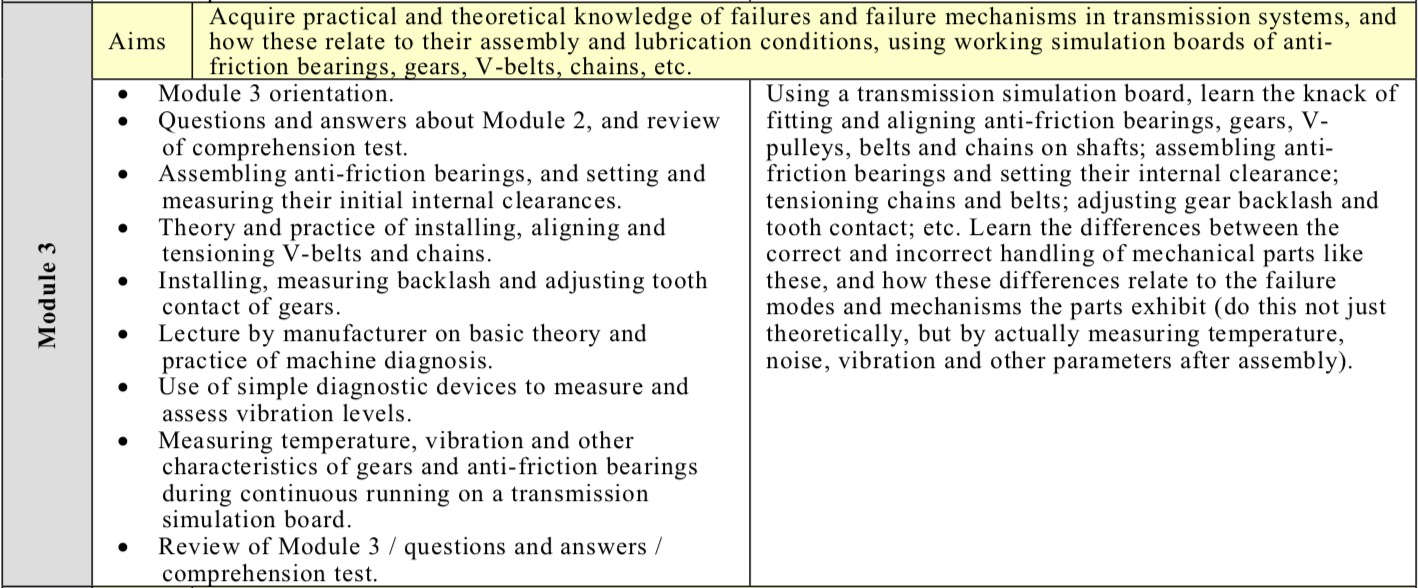

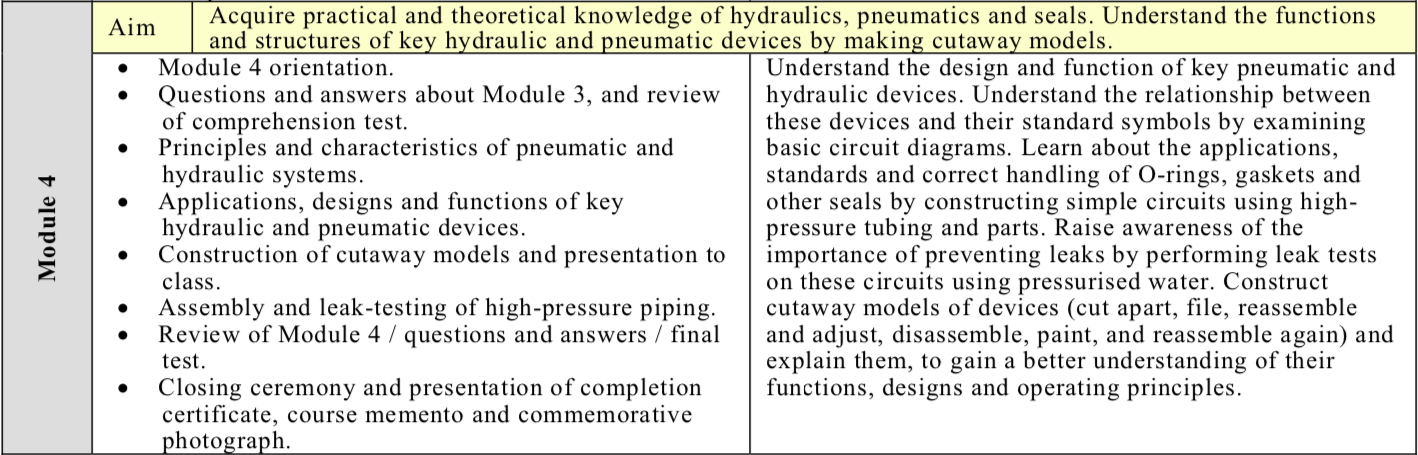

Step 3: Upgrade Operating and Maintenance Skills

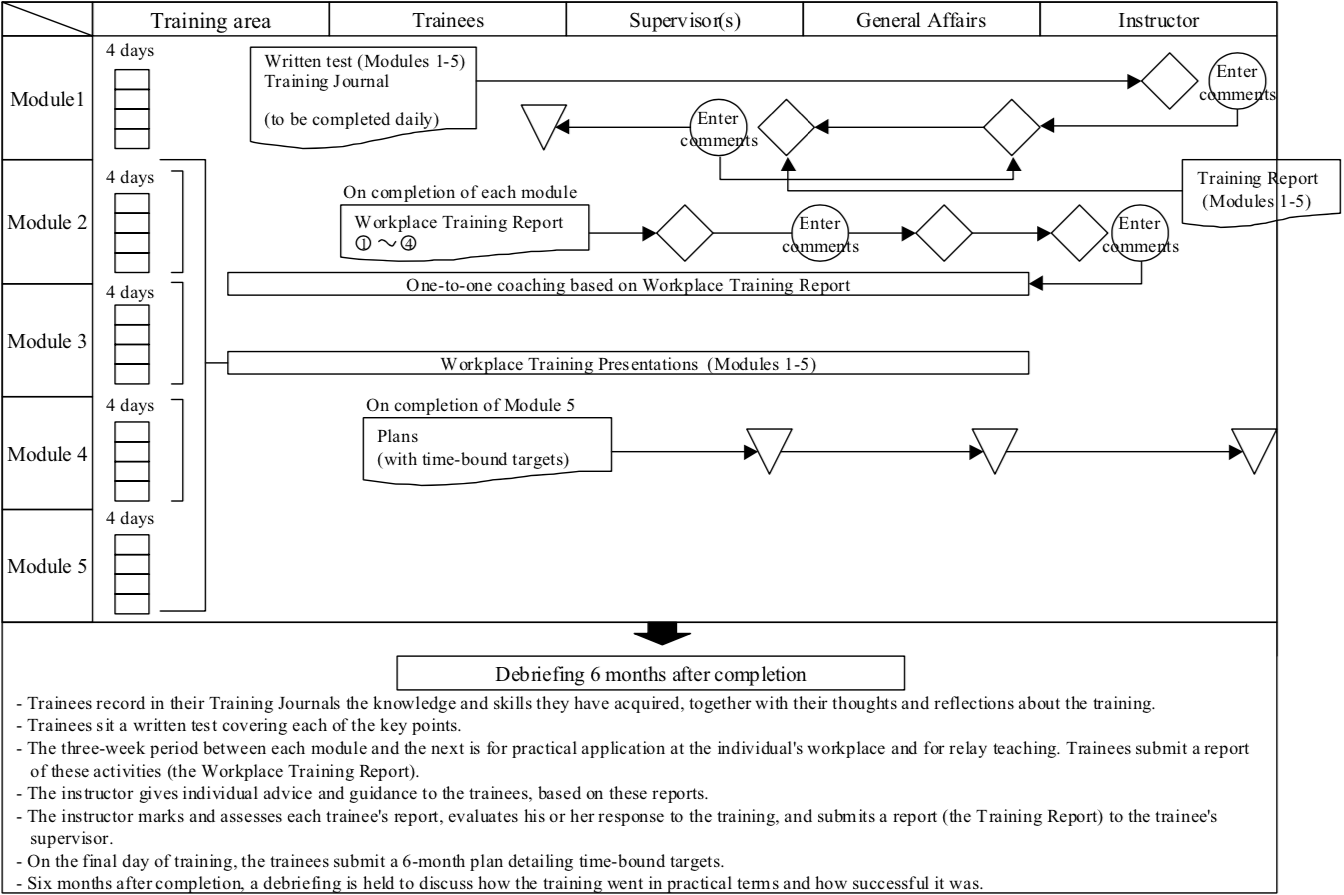

Linkage of training to work

Skills can be mastered much more effectively if learning opportunities are linked directly to what people actually do at their places of work, as illustrated in the figure below

Aims

The purpose of technical training is to upgrade the skills of operators and maintenance personnel in response to modern advances in automation, mechatronics, etc., and develop people with a sound understanding of the equipment they are responsible for.

Practical agenda

- Develop instructors to teach maintenance skills

- Select key maintenance personnel and shop-floor leaders, and develop them into instructors by sending them on external or internal maintenance skills courses.

- Upgrade operators’ operating skills

- Carry out training to improve operators’ basic operating skills.

- Carry out training to improve changeover, adjustment, tool replacement, and other skills as required.

- Train operators in maintenance skills

- Train operating team leaders in maintenance skills, using in-house instructors.

- Having received the training, the leaders then train the members of their own teams (“relay teaching”).

- The team leaders prepare collections of one-point lessons, cutaway models, etc. as teaching materials for use in teaching the operators

- Upgrade maintenance personnel skills

- Train all maintenance personnel in maintenance skills, using in-house instructors.

- Encourage them to acquire nationally recognized maintenance skills qualification.

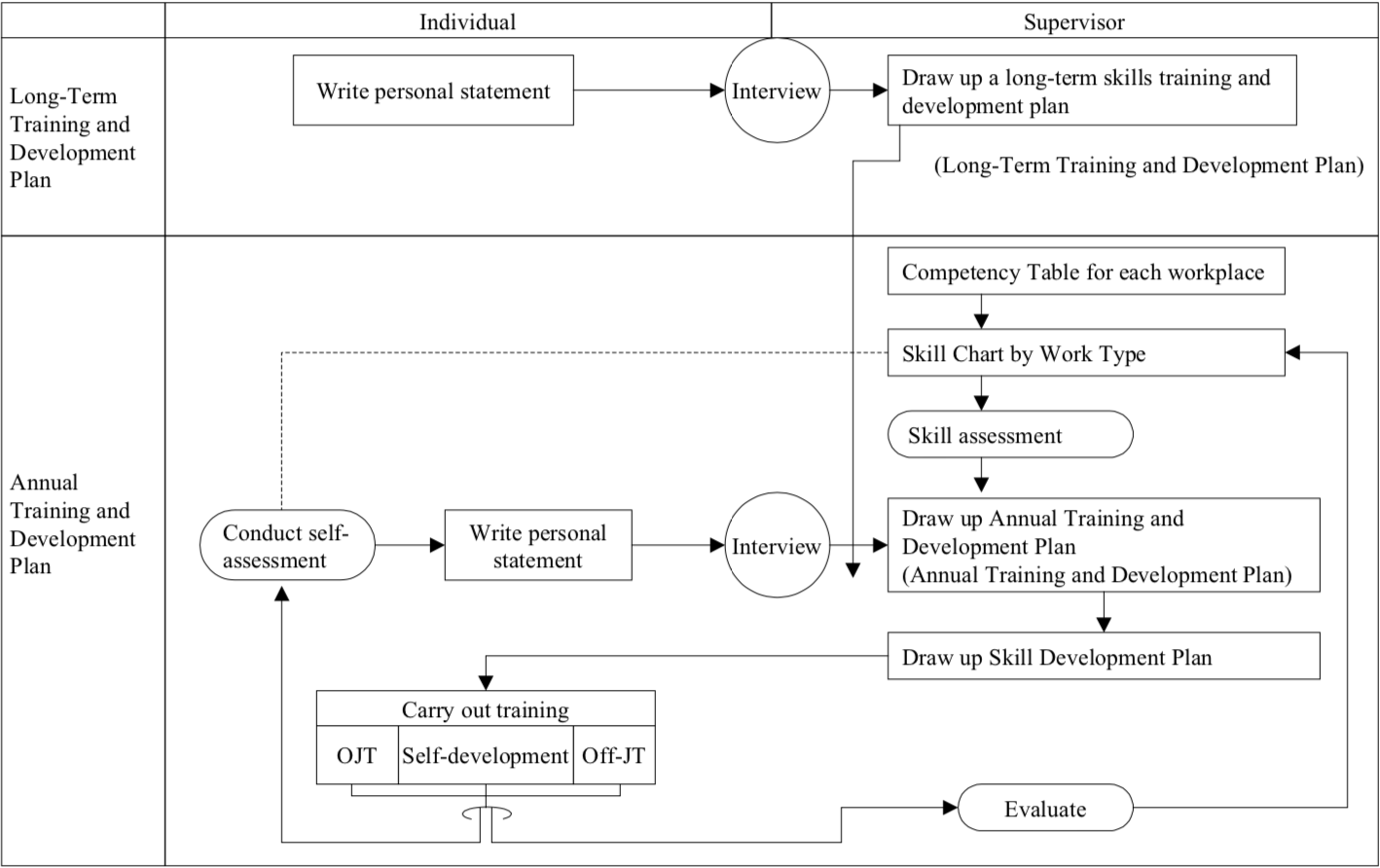

Step 4: Establish Systems to Further Develop and Enhance Abilities

Link to Autonomous Maintenance Step 4

It is best to combine technical operating skills training with the training given in Step 4 of the Autonomous Maintenance program.

The role of managers

- Secure the funds needed for technical training

- Review the company’s technical training program and emphasize the importance of people development.

Key points for training to improve people’s ability to get the job done

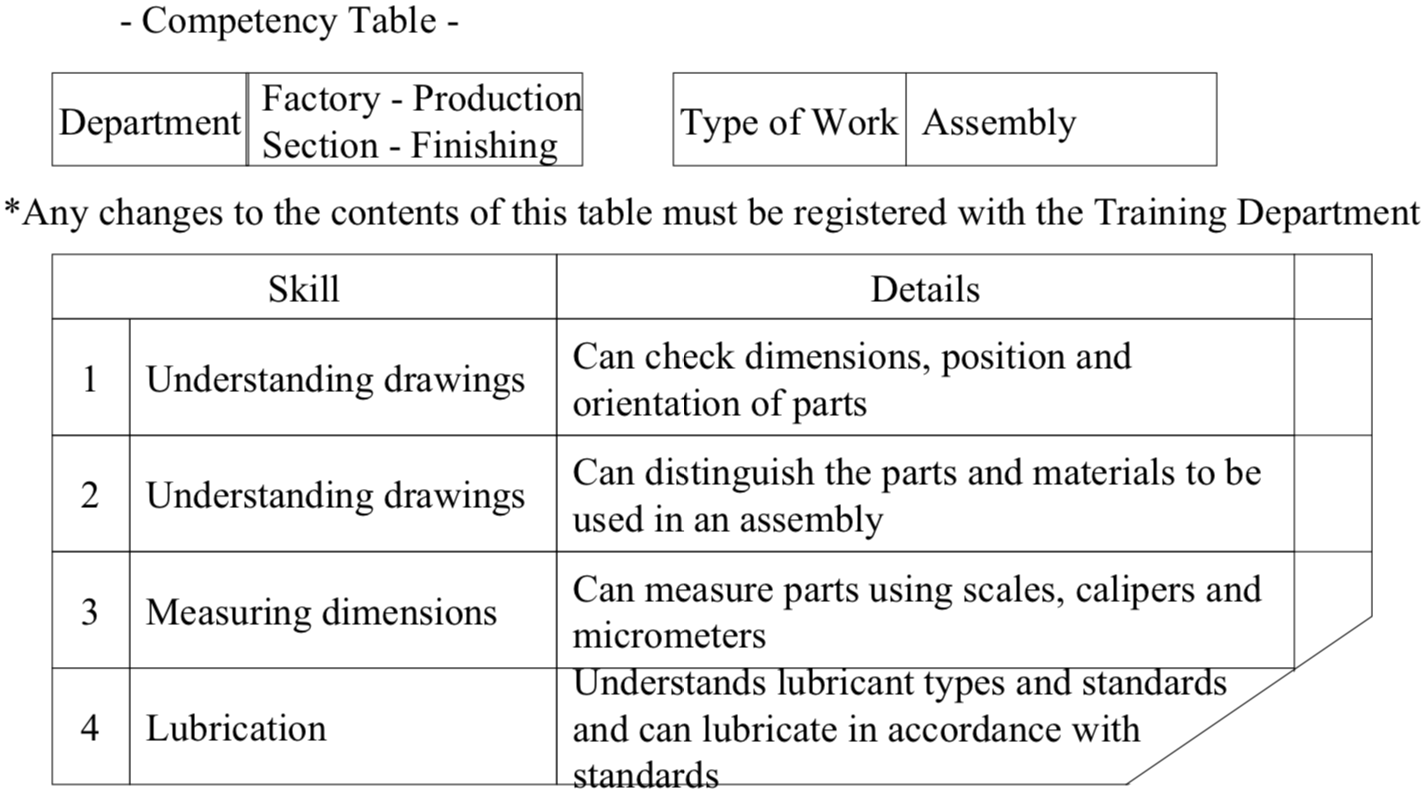

The training and development program should be based on on-the-job training and self-development. Training and development plans should take account of the needs of the individual.

- It is important to establish what skills, knowledge and qualifications are needed for the job, devise a training plan that takes into account the development needs of the individual, and carry out regular assessments as the course progresses.

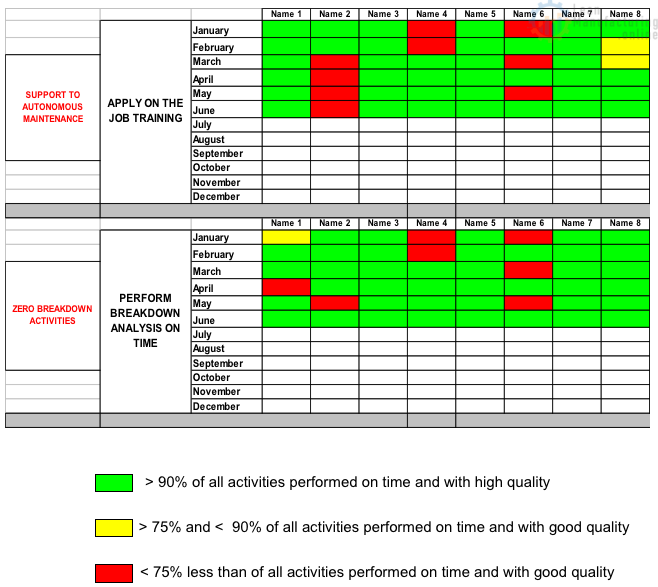

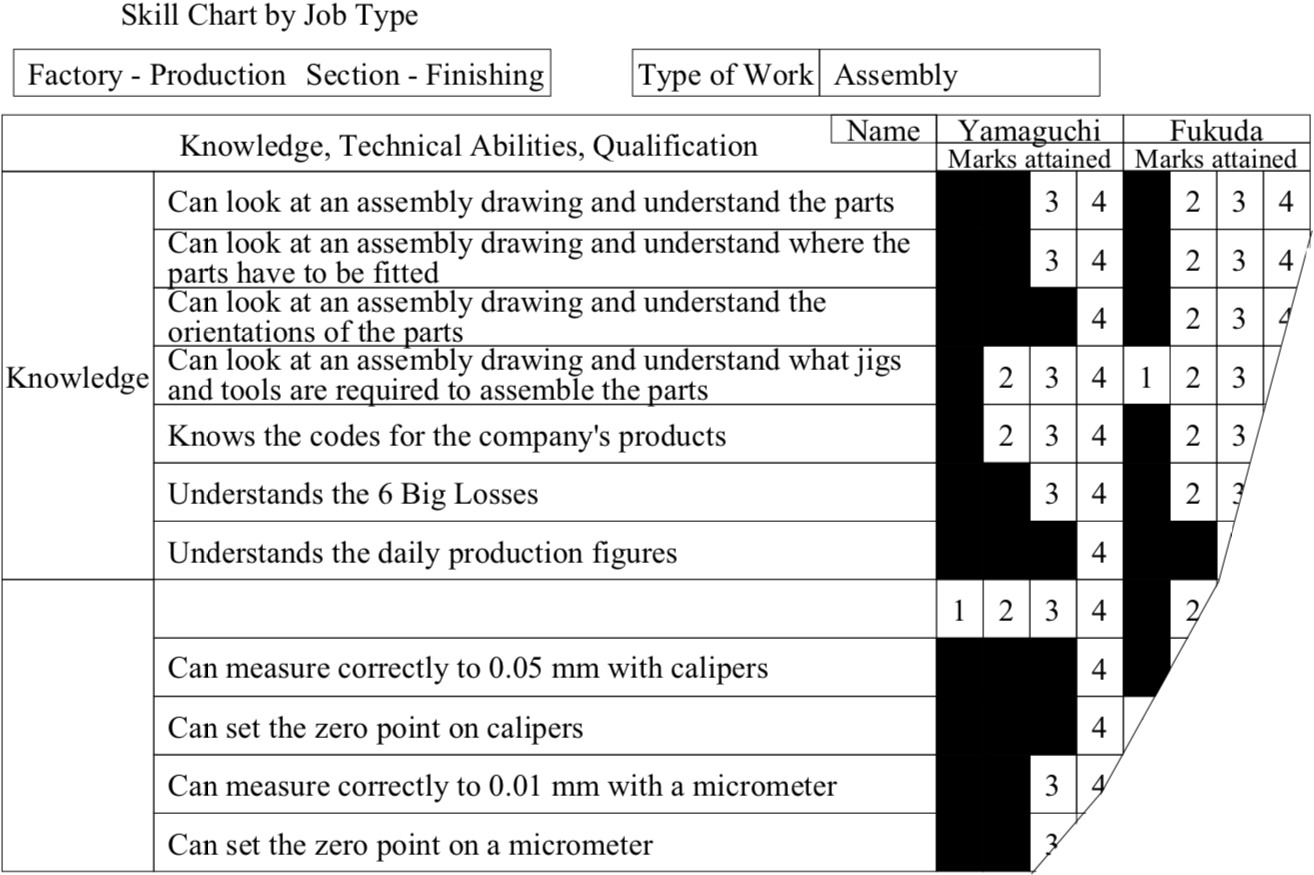

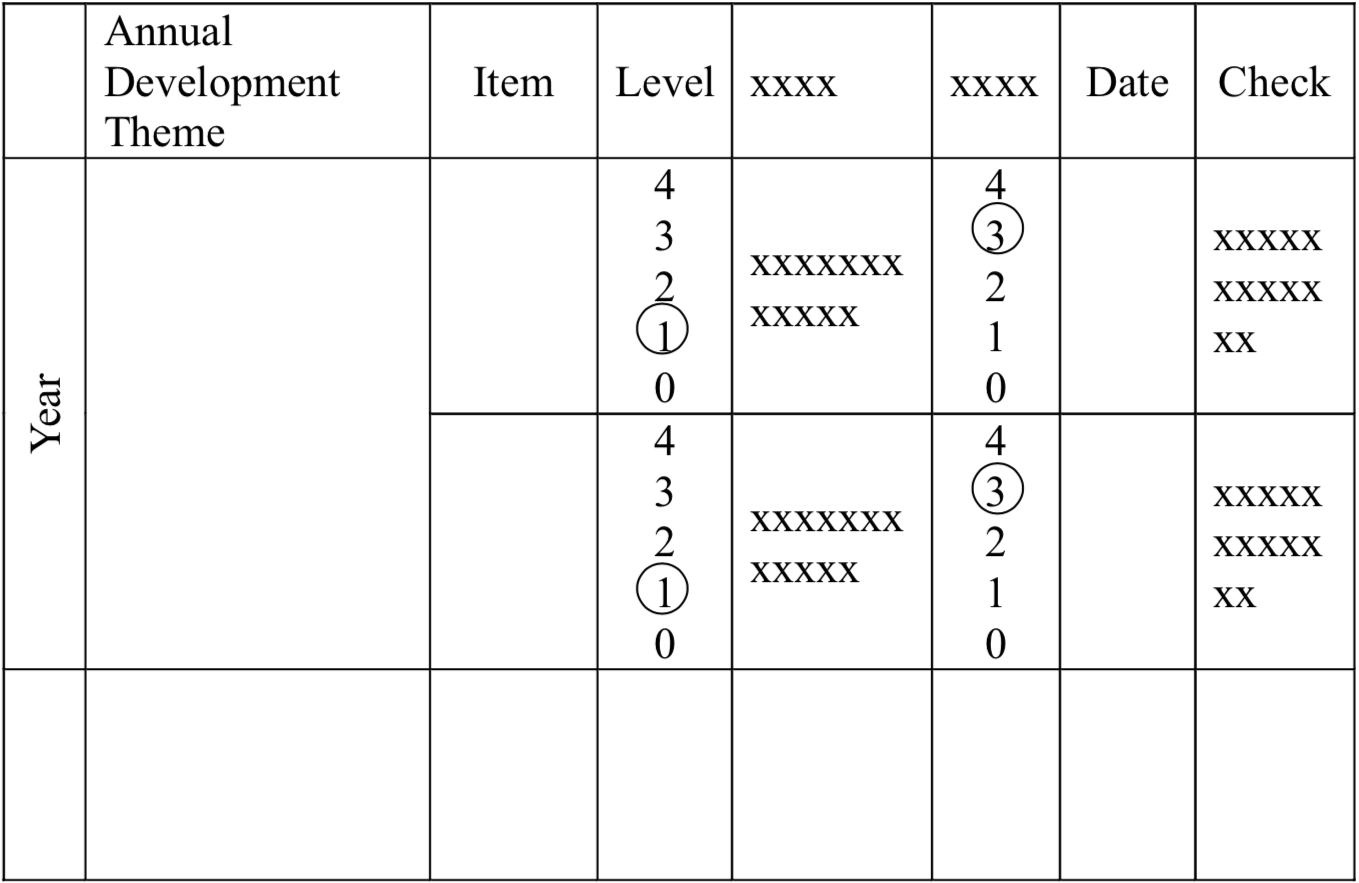

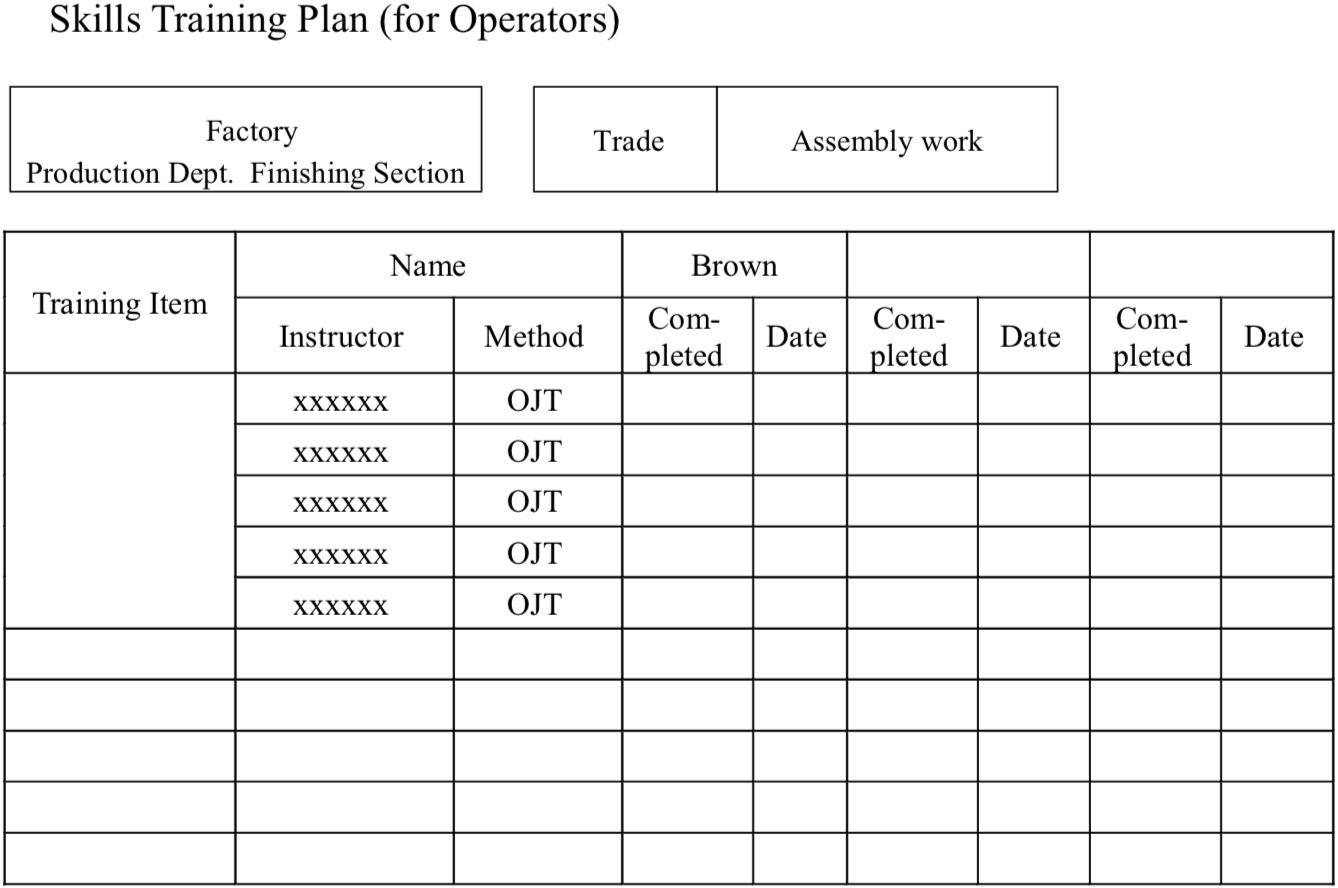

- Personal training and development plans should be implemented systematically in accordance with a system like that shown in Table “Competency Table”, “Skill Chart by Job Type”, “Annual Training and Development Plan”, “Skill Development Plan” using a combination of on-the-job training, self-development, and off-the-job training.

Step 5: Create an Environment that Encourages Self-Development

Every company should create a training environment suited to its needs, with distance learning, video training, literature, assistance with funding, and other training opportunities made available to employees. All employees should be assigned a new self-development topic every six months, and progress against targets should be monitored. They should also be given the chance to acquire nationally recognized qualifications. Operators’ Autonomous Maintenance skill levels should be raised by encouraging them to study for tests such as the Autonomous Maintenance Practitioner Test.

Step 6: Evaluate Program So Far, and Decide on Future Direction

Regularly evaluate progress made against the training plans to see how well the necessary skills are being developed in individuals in every type of job and at each level of the organization. Technology, equipment, and management approaches are advancing day by day, and the company’s training and development program must keep pace with and even anticipate these changes. This makes it essential to continually monitor the contents of the program and the results it is producing, supplementing, and enhancing it wherever necessary.