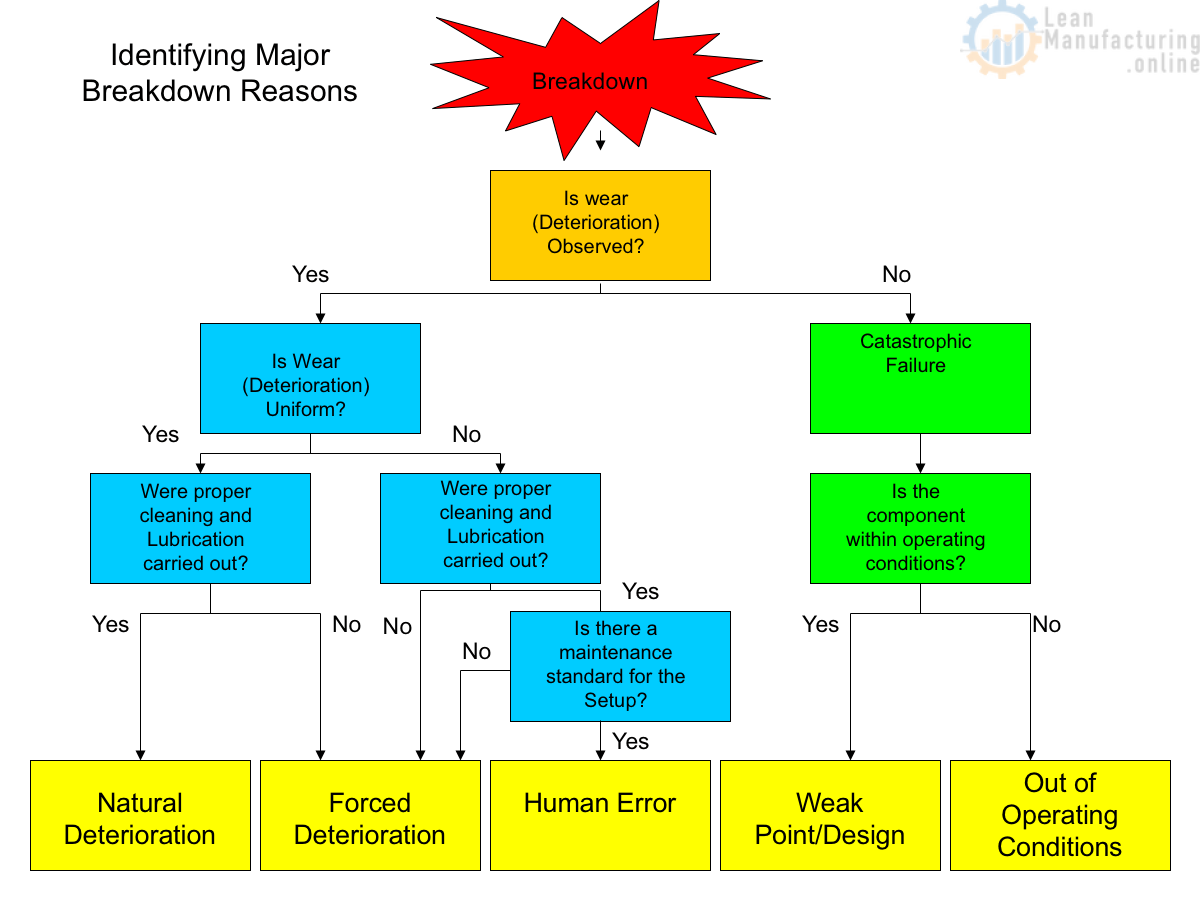

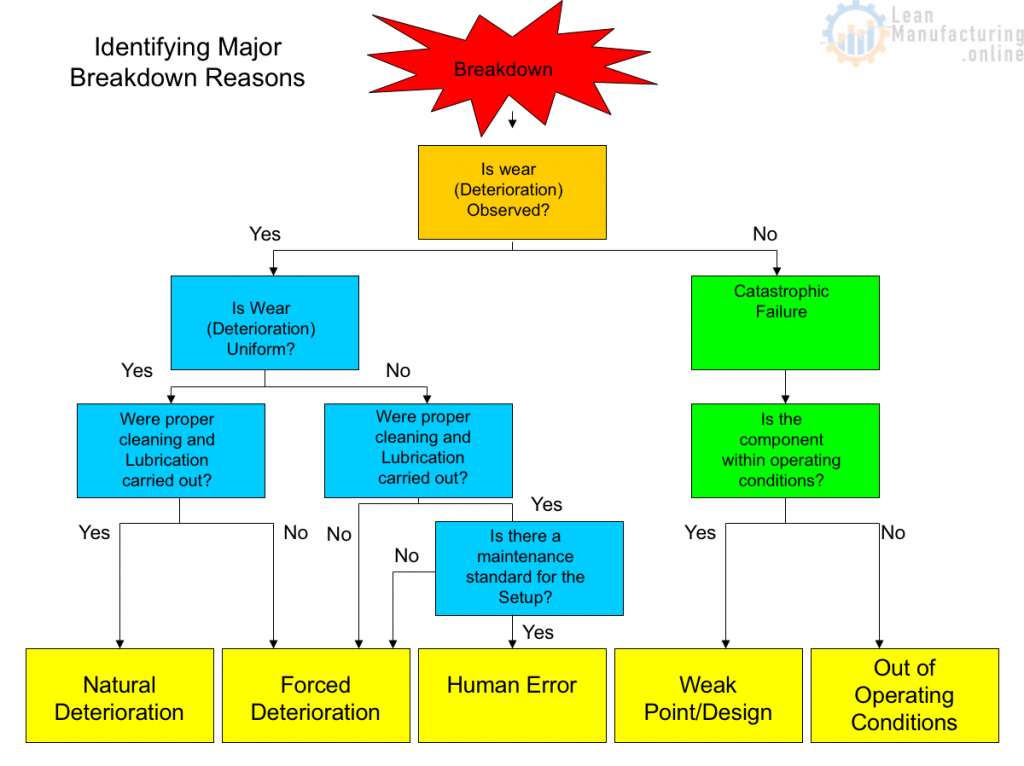

After completing Breakdown Analysis, one of the outcomes will be Human Error or Lack of Knowledge, meaning breakdown occurred due to:

- no Standard Operating Procedures (SOP) or Training Process Guide (TPG) in place

- equipment setup instructions were missing or poorly expained

- OEM training wasn’t completed for all maintenance technicians (mechanics, millwrights, electricians etc.)

- new assemblies or equipment were added to existing production line without updating current SOPs, TPGs or any other training materials

- process change was implemented but no proper training updates provided

To avoid or reduce breakdowns due to lack of knowledge, Recurrence Matrix (RM) can be implemented and should be updated on annual basis. Also updates to the matrix should occur if process or piece of equipment was modified.

RM example can be found here: future link to RM

Another tool should be implemented – Annual Training Plan (ATP). Even though ATP usually owned by Education and Training Pillar, it must be linked with Recurrence Matrix to make necessary adjustments based on breakdowns occurred.

Annual Training Plan example can be found here: future link to ATP