1. The Need for Training and Development

Companies progress by developing their employees’ capabilities and maximising their ability to work effectively. The object of a TPM programme is to build a corporate organisation and culture that continuously evolves in response to changes in the economic environment, technical innovations, the introduction of more advanced equipment, and the development of more up-to-date management practices – and the first essential requirement for this is to have people who are thoroughly conversant with their equipment and competent at their jobs.

If a company wants to put an effective training and development system in place, the first thing it must do is identify the gap between the knowledge and skills it needs and the knowledge and skills it currently possesses. It must then prepare the training materials, systems and facilities required to close that gap. Finally, after implementing the training, it must review the results. The specific procedure for doing this is as follows:

(1) Clarify the business strategy

(2) Sort out what knowledge and skills the company needs (prepare a technology/skill map)

(3) Assess the current situation (identify what training is needed)

(4) Prepare training manuals

(5) Formulate and implement a training plan

(6) Evaluate and certify the training

This chapter focuses on the operating and maintenance skills training that should be

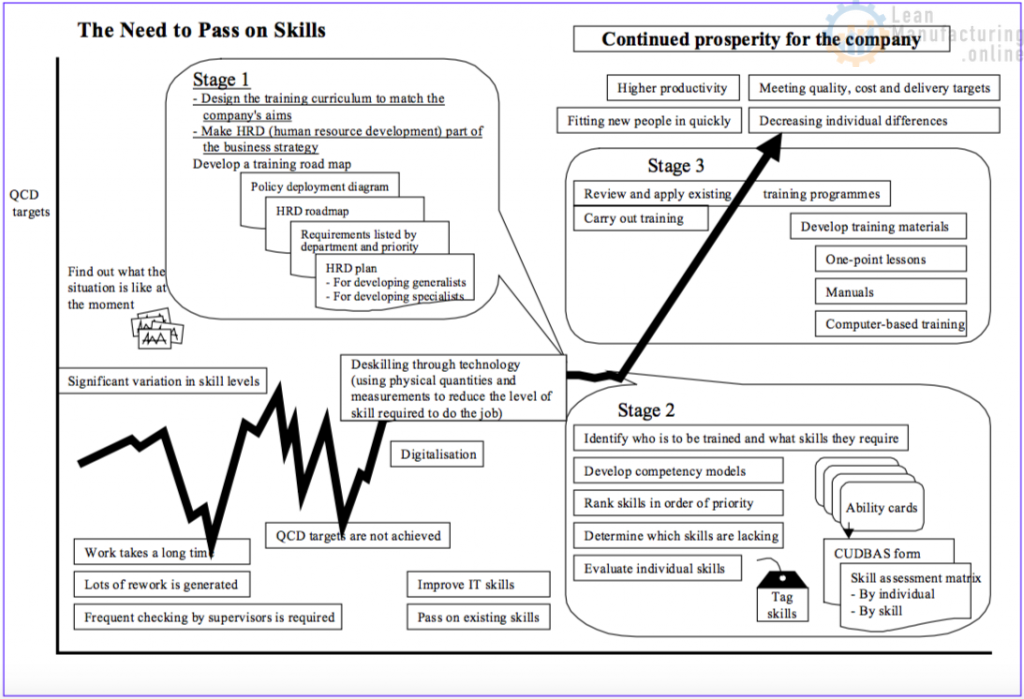

carried out right away, as soon as a TPM programme is started. These methods and approaches can also be used in other situations, Of course, it goes without saying that a training and development programme can only deliver good results if the methods used are tailored to the work responsibilities, abilities, individual characteristics and specific requirements of individual trainees (see Figure 9.1).

Figure 9.1

2. The Basic Philosophy Behind Training and Development 2.1 What is Skill?

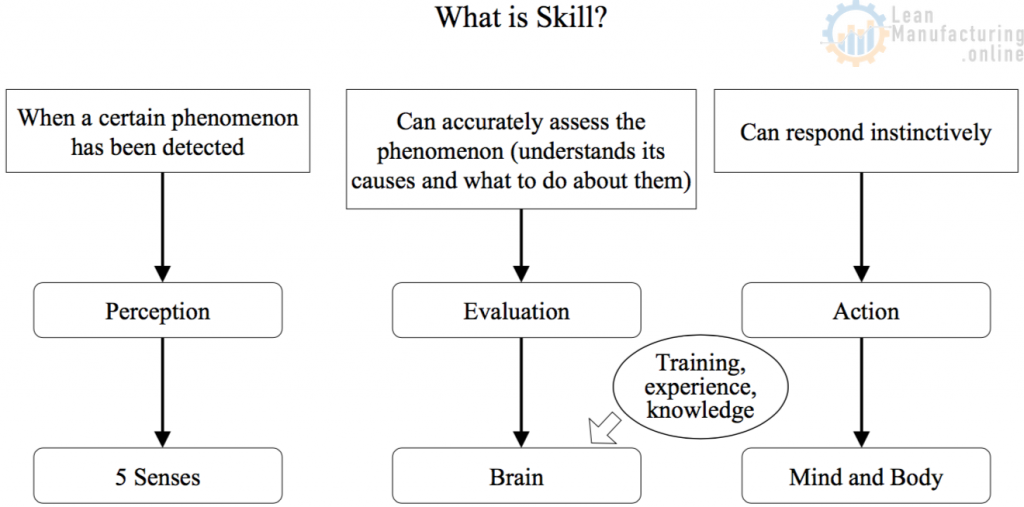

Skill is the ability to do one’s job effectively. As Figure 9.2 illustrates, it has been defined as ‘the ability to continue to act instinctively (i.e. without thinking) and correctly over a sustained time period in relation to various phenomena, based on knowledge acquired’. The quicker a person can discover and solve problems, the more skilled he or she is. Skill can only be developed through training and the systematic acquisition of knowledge and experience. The highest level of skill, or ‘mastery’, is achieved through good training combined with personal motivation, and is what any self-respecting training and development programme should aim at.

2.2 The 5 Steps to Mastery

2.2.1 The 5 Steps

The first step in establishing a training and development programme is to work out what levels of understanding, knowledge and ability each individual needs in order to do his or her job effectively (taking account of forthcoming advances in engineering technology and management technique), and assess the level that individual has currently achieved. Much of the training that companies give their employees is ineffective because it fails to cover the necessary topics as and when needed. It is important to establish a thorough, down-to-earth system of training and development that focuses on improving areas of weakness one step at a time.

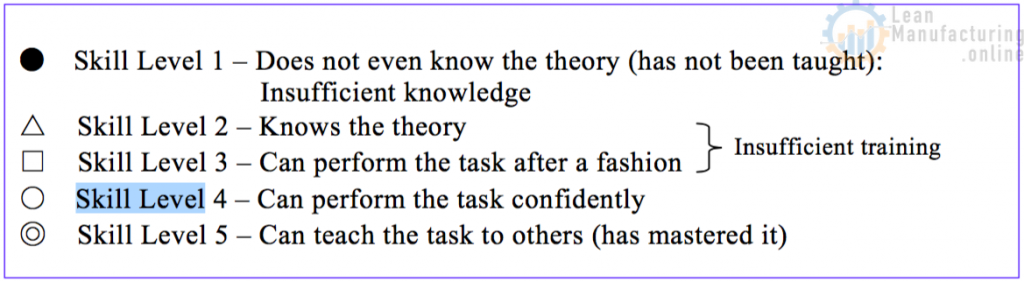

The 5 steps to mastery can be classified as follows:

Figure 9.2 What is Skill?

A function of time

2.2.2 Assessing skills

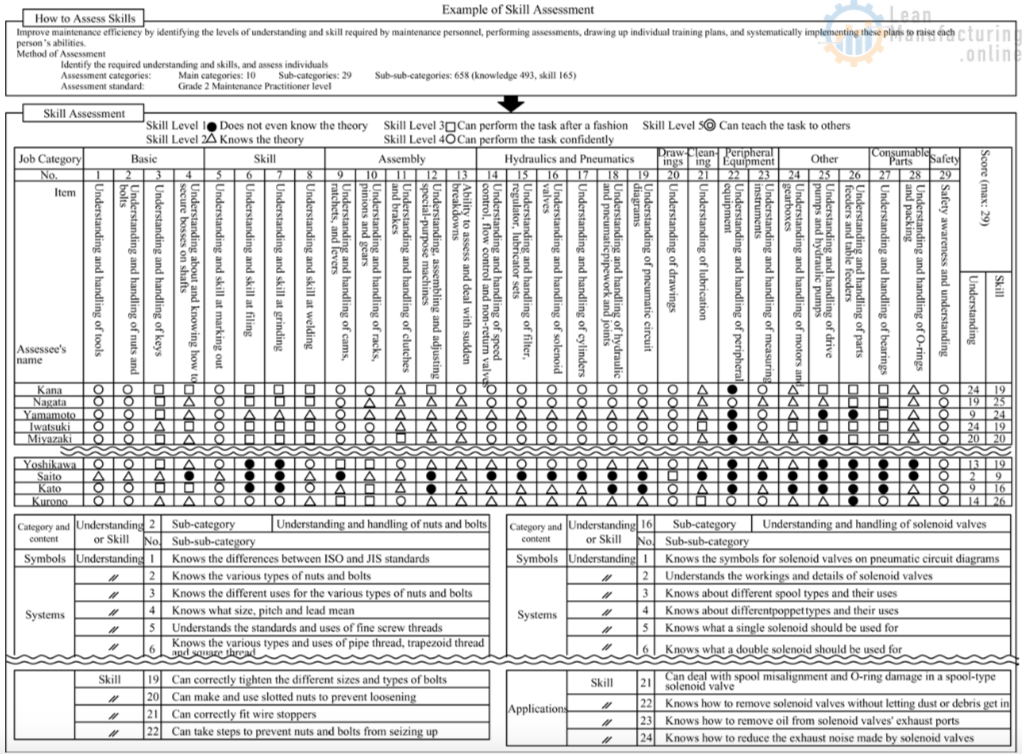

To train individuals effectively, it is first necessary to assess the levels of understanding, technical ability and skill they will need for the types of job they will do and the positions they will occupy, as in the example shown in Figure 9.3. Plans must then be put in place to systematically upgrade their expertise and fill in any gaps. After the skills and level of ability required by each individual have been identified, development targets should be set. The progress of the individual’s training plan should then be monitored, and the degree to which they have improved should be periodically assessed.

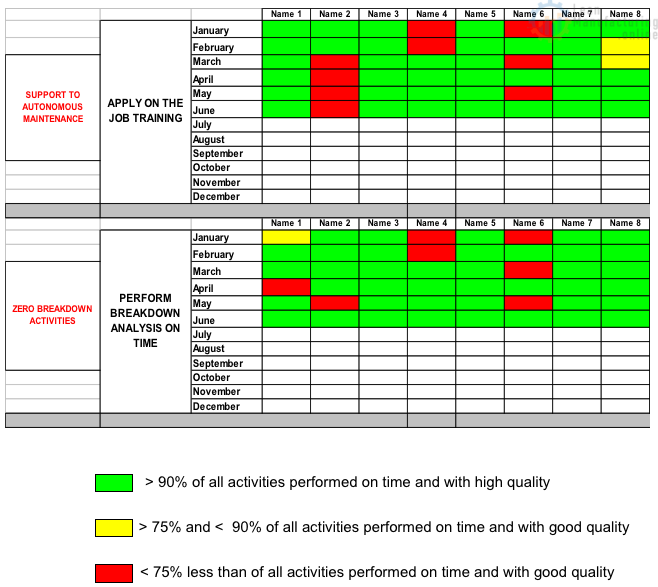

Figure 9.3 Example of Skill Assessment

2.3 The Abilities Most Needed in Operators

Apart from being able to operate and adjust their equipment correctly, operators need to be fully capable of:

2.3.1 Detecting problems with the equipment and carrying out continuous improvement

Specifically, they must:

- Be able to detect problems with their machinery.

- Understand the importance of lubrication, and know how to lubricate their

equipment correctly and check the results. - Understand the importance of checking through cleaning and know how to do it

properly. - Understand the importance of localising the spattering of coolant, swarm or other

debris, and be able to do the necessary improvements. - Be able to restore or improve their machines to eliminate faults that they

themselves have discovered.

2.3.2 Understanding the structure and functions of their machinery, and discovering the root causes of abnormalities

Specifically, they must:

-

- Understand which parts of their machines they must pay particular attention to.

- Be able to clean and check their machines properly in order to maintain their

performance. - Understand the criteria for deciding whether or not something is wrong.

- Understand the root causes of abnormalities.

- Be able to make sound judgements about whether or not to stop the machinery

when problems are found. - Be able to diagnose breakdowns to some extent.

2.3.3 Understanding the relationship between machinery and quality, and foreseeing and detecting quality problems

Specifically, they must:

-

- Be able to do a physical analysis of problem phenomena.

- Understand the relationships between machinery and quality characteristics.

- Understand the range within which the static and dynamic precision of

machinery must be maintained, and be able to check these. - Understand the root causes of quality defects

2.3.4 Carrying out repairs

Specifically, they must be able to:

- Replace parts.

- Estimate how much longer parts will last for.

- Work out the root causes of breakdowns.

- Install temporary solutions to problems.

- Assist with overhauls.

2.3.5 Doing Focused Improvements on suitable topics, either independently or with other departments

Specifically, they must:

-

- Be concerned about avoiding waste, and be able to reduce the time taken for

cleaning, lubricating, checking, changeovers, and adjustments. - Be able to carry out improvements to extend the life of machine parts.

- Be able to predict breakdowns and minor stops, and carry out improvements to

reduce them. - Be able to carry out improvements to extend the life of cutting tools and reduce

cutting-tool replacement losses. - Be able to carry out improvements to reduce speed losses.

- Be able to carry out improvements to reduce quality defects.

- Be able to improve methods and procedures.

- Be able to improve the safety of work and machinery.

- Be concerned about avoiding waste, and be able to reduce the time taken for

These skills are developed through participation in Autonomous Maintenance, Focused Improvement and Quality Maintenance, eventually leading to operators knowing their equipment so well that its operation and maintenance become second nature to them.

2.4 The Abilities Most Needed in Maintenance Staff

Maintenance personnel need to be able to do the following:

-

- Instruct operators in daily maintenance and the correct handling of machinery.

- Know when something is not right with the equipment.

- Investigate the root causes of problems and solve them correctly by the most

appropriate methods. - Increase the reliability of machines and components, make them last longer, and minimise the rate of occurrence of breakdowns and other such problems (i.e. extend the MTBF, or mean time between failures).

- Increase equipment maintainability (e.g. by making it possible to replace complete units instead of individual parts) in order to minimise the time spent on repairs (i.e. reduce the MTTR, or mean time to repair).

- Acquire and apply diagnostic techniques and develop standardised ways of using them.

- Optimise all of these activities and maximise their cost benefits.

As production equipment becomes increasingly sophisticated and levels of automation rise, maintenance personnel become more and more extensively involved with programmes for enhancing safety, preventing pollution, saving energy and so forth, in addition to their normal maintenance duties. This makes it essential for any company to define the technical skills it needs, establish effective development and training curricula, and systematically implement internal and external training programmes closely tailored to its requirements.