The Lean concept of identifying and eliminating waste through improved workplace organization.

A 5S approach allows you to rethink the layout of the work cell, whether front-line production, storage, or office.

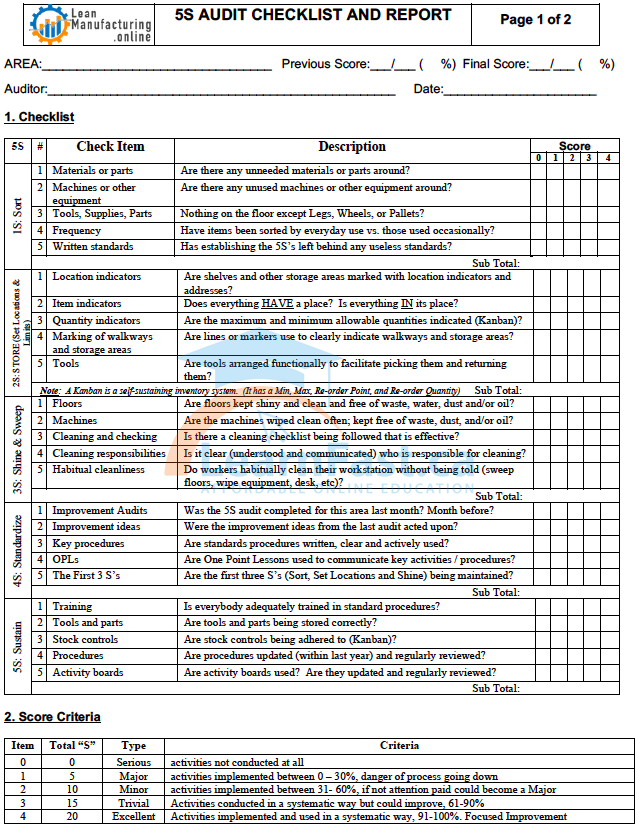

To be successful in implementing 5S (Sort, Set, Shine, Standardize, Sustain), audits must be conducted, and four simple rules must be followed:

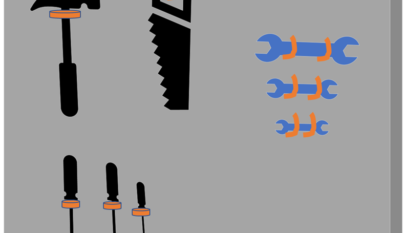

- Everything HAS a place, and everything is IN its place.

- Nothing on the Floor except Legs, Wheels, or Pallets.

- Clean to Inspect, Inspect to Detect, Detect to Correct, Correct to Perfect.

- When in doubt, throw it out.

The template can be downloaded here.

New!!! Updated on 18-Sep-2025

This spreadsheet was created by Nilson Rodrigues da Silva

An interactive 5S spreadsheet can be downloaded here: https://zbk.li/dBotv