Objectives

- What is Autonomous Maintenance Step 3?

- What are some of the main activities?

Prerequisites

- AM Introduction

- AM Preparation for F-Tags and OPL’s

- AM Step 0 (5S and Zero Energy State)

- AM Step 1 and AM Step 2

Step 1:

- Learning

- Defect ID, Basic

- 5W-1H

- Clean

- F-tag

- Abnormalities 80% clear

- Cleaning Standards

- Inspection Standards

- Abnormalities

- ID SOC/HTA

- OPL’s

Step 2:

- Learning

- Principle of Operation

- Why-Why, 12 Step QC

- Clean

- F-tag

- SOC/HTA 80% clear

- Cleaning Standards

- Inspection Standards

- Abnormalities

- Correct SOC/HTA

- OPL’s

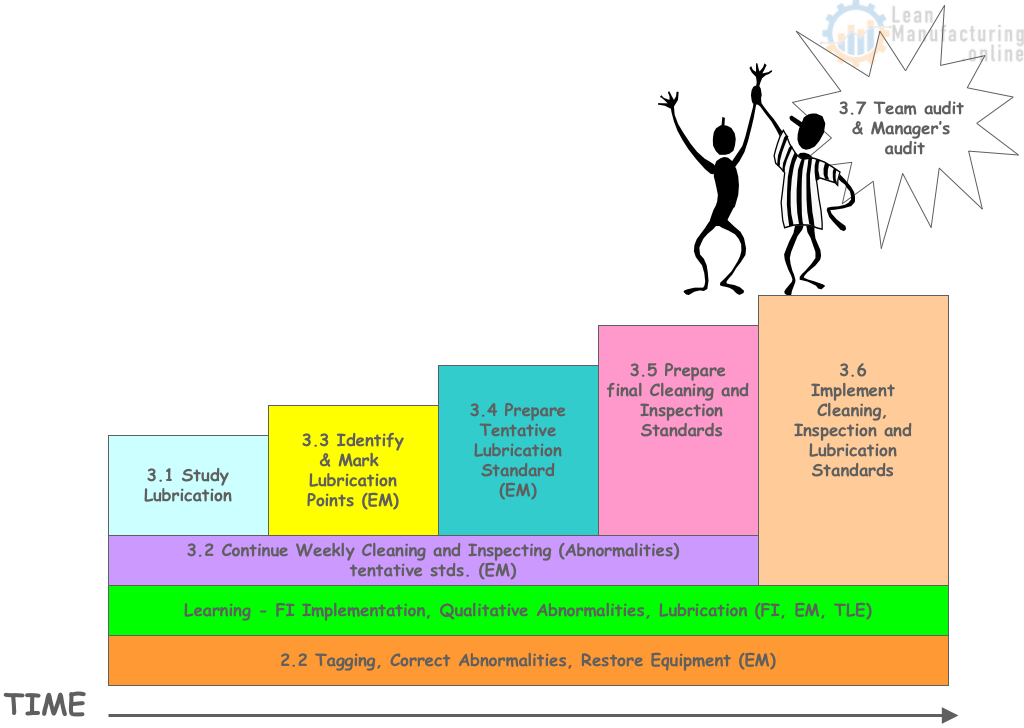

Step 3:

- Learning

- FI implementation

- Clean

- F-tag

- 85% completion rate

- Cleaning Standards

- Inspection Standards

- Qualitative

- Lubrication Standards

- OPL’s

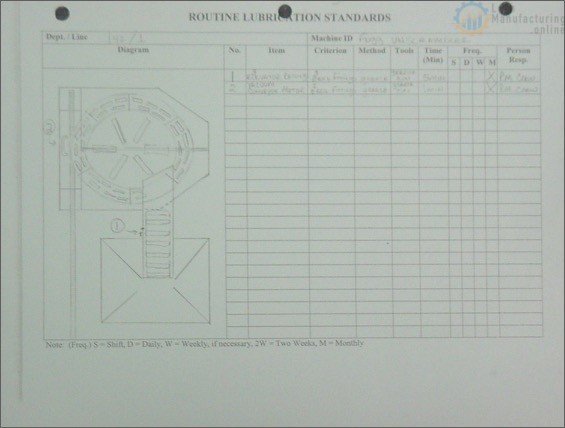

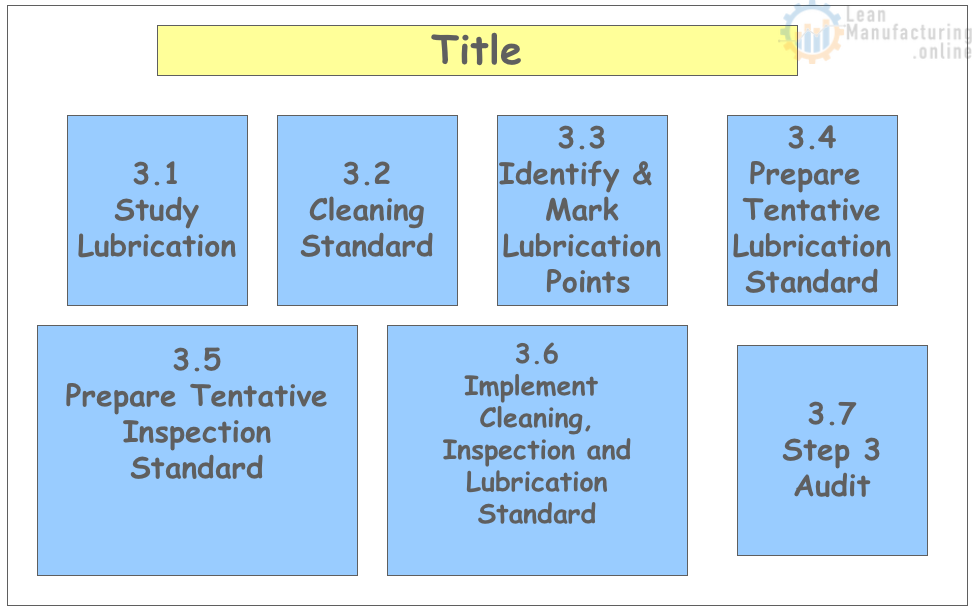

3.1 Study Lubrication

- Ensure RIGHT lubricant is being used

- MINIMIZE types being used

- Identify frequencies

- Identify types and usages

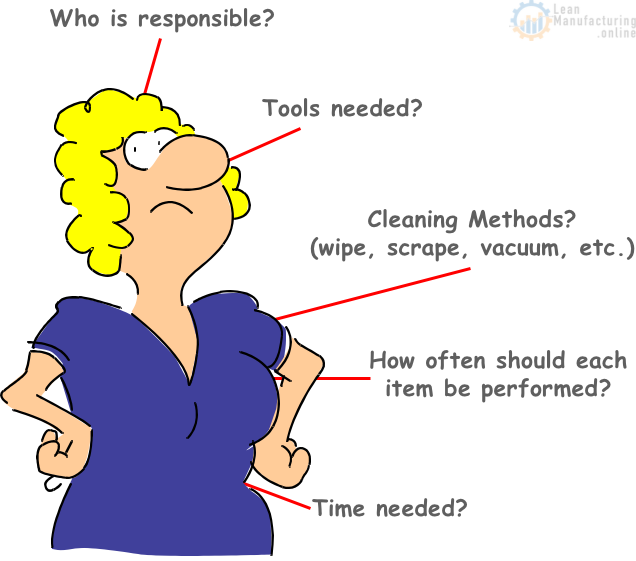

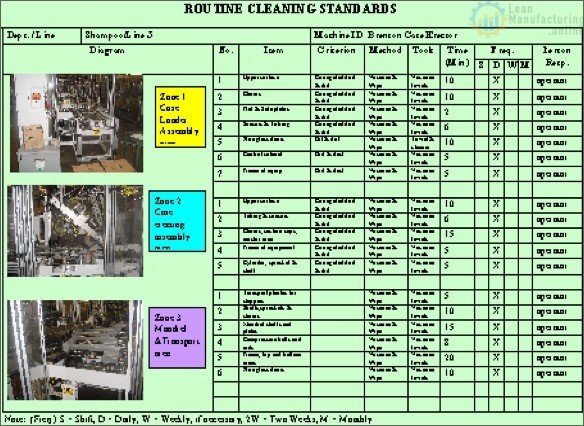

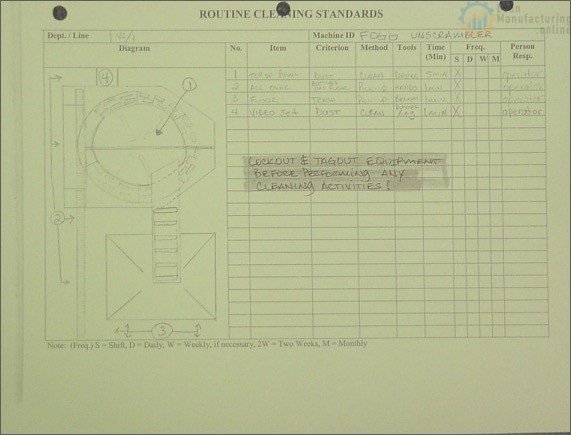

3.2 Cleaning Standard

- Prevent FORCED DETERIORATION

- Continue to MEASURE time to complete

- Continue to Eliminate,Contain,Redesign and Improve system to eliminate S.O.C.

- Prepare cleaning revision and implement

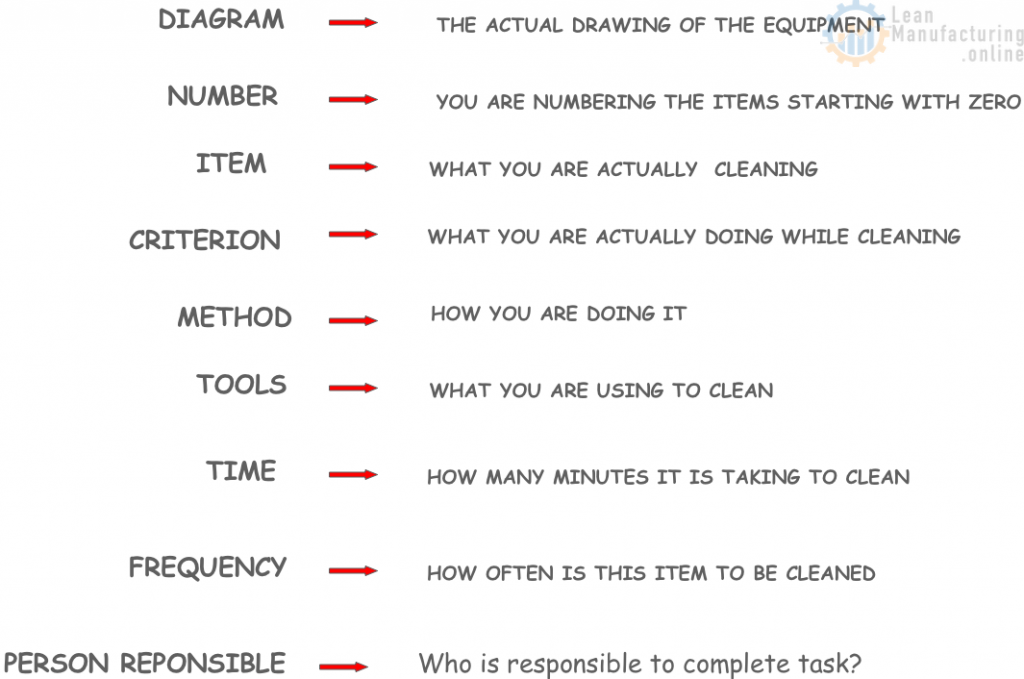

ROUTINE CLEANING STANDARD EXPLANATIONS

Updated Cleaning Standards

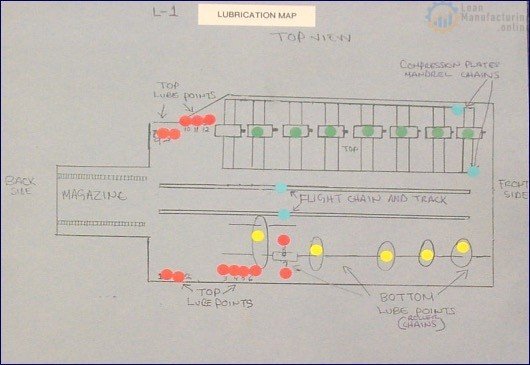

3.3 Identify & Mark Lubrication Points

Types of Lubricants:

- Master List

- Lubrication Engineers

Lubrication Map

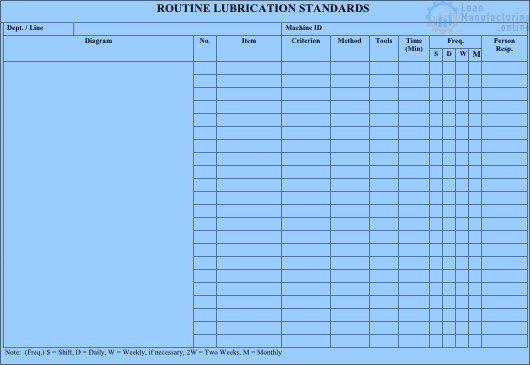

3.4 Prepare Tentative Lubrication Standard

Types of Lubricants:

- Standards

Routine Lubrication Standards

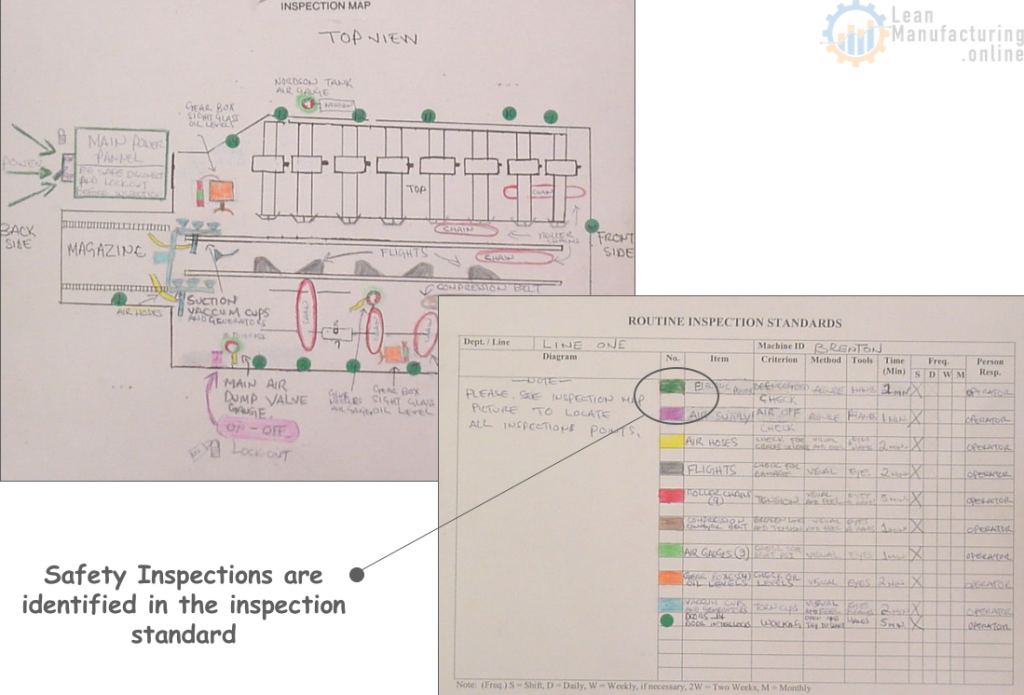

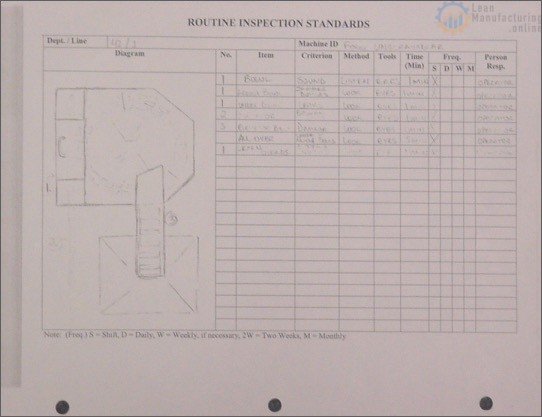

3.5 Prepare Tentative Inspection Standard (Including Safety)

- Identify methods and criteria for inspection of equipment

- Identify locations

- Identify the what and how

- Identify inspection time frames

Safety Inspections are identified in the inspection standard

3.6 Implement Cleaning, Inspection and Lubrication Standards

- Create OPL’s for the implementation of standards

- Establish new methodology while having control of the process

- Use standards and revise

- Ensure equipment maintains PEAK performance

- Identify improvements

3.7 Team audit & Manager’s audit

Step 3 Board

Requirements:

- OPL on Lubrication Study

- Lubrication Map identifying and marking lubrication points

- Tentative Lubrication Standard

- Tentative Inspection Standard

- Create OPL’s for the implementation of standards

- Finalize Cleaning, Inspection and Lubrication Standards

- Step #3 Audit

I want to required pdf file of am maintenance

Thanks for your request. We are currently working on .pdf version for each TPM pillar manual, for now you can browse Autonomous Maintenance chapter of TPM Instructor Course.

Great article to illustrate why and how to do AM. Is there any AM step 1-7 audit template?

I want the template of step audit sheet

Thanks for you interest. Some of the templates can be reviewed here: http://leanmanufacturing.online/wp-content/uploads/2017/09/Examples-of-Autonomous-Maintenance-review-sheets-LeanManufacturing.Online.pdf