AM Step 0: SAFETY

Objectives:

- Safety Comes First

- Ensure team members are safe before performing any of the activities

- Learn some of the basic TPM tools (activity boards, OPLs, teamwork, etc.)

AUTONOMOUS MAINTENANCE STEP 0 – AUDIT TEMPLATE can be downloaded here

AM Step 1: CLEANING IS INSPECTION

Objectives:

- Restore equipment to its normal operating condition

- Through cleaning, learn the technical details of how the equipment functions (ie. Know your line)

- Identify and correct abnormalities through cleaning (Key Tool: F-Tag)

- Identify Sources of Contamination and Hard to Access Areas

- Generate a tentative Cleaning Standard

AM Step 2: Eliminate SOCs & HTAs

Objectives:

- Implement Countermeasures for SOCs & HTAs (Key Tools: F-Tag and ECRS Methodology)

- Learn Kaizen activities (continuous improvement)

- Learn root cause analysis tools by conducting breakdown analyses (Key Tools: 5W 1H and 5 Why Analysis)

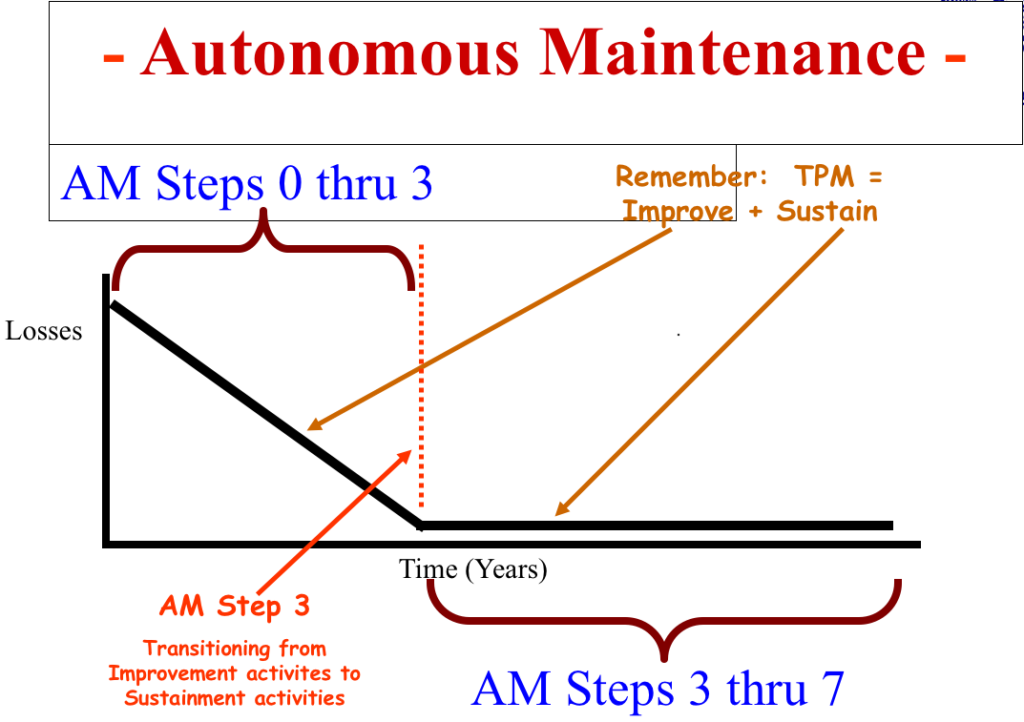

AM Step 3: Tentative Standards

Objectives:

- Implement tentative (initial) standards for:

- Cleaning

- Inspection

- Lubrication

- Begin to transition from Improvement activities to the Sustaining phase of AM