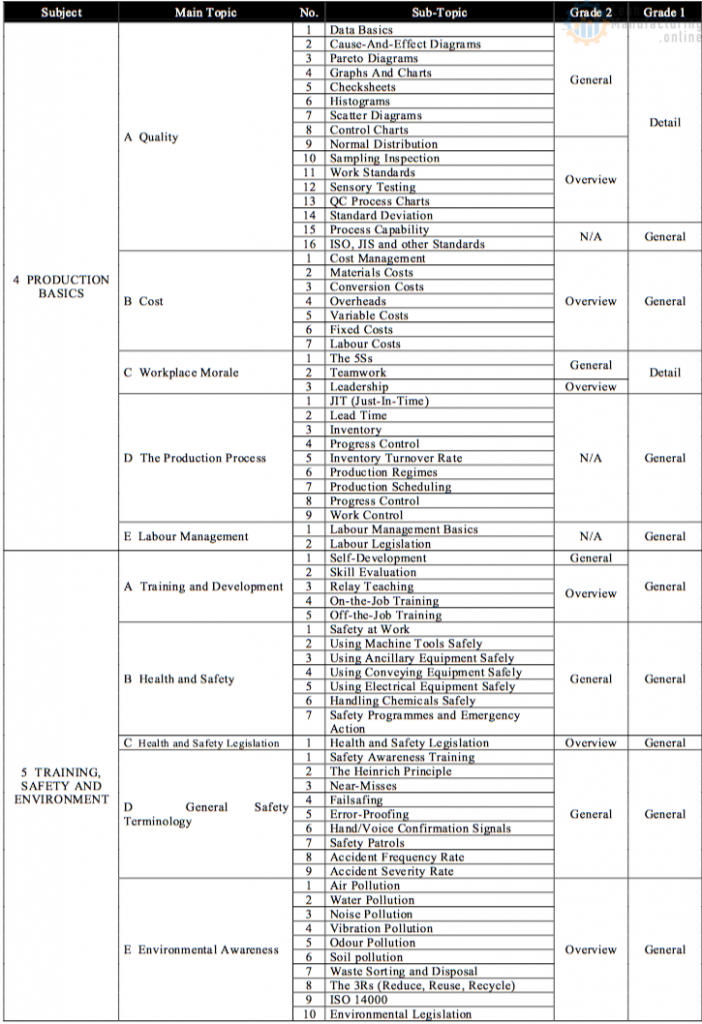

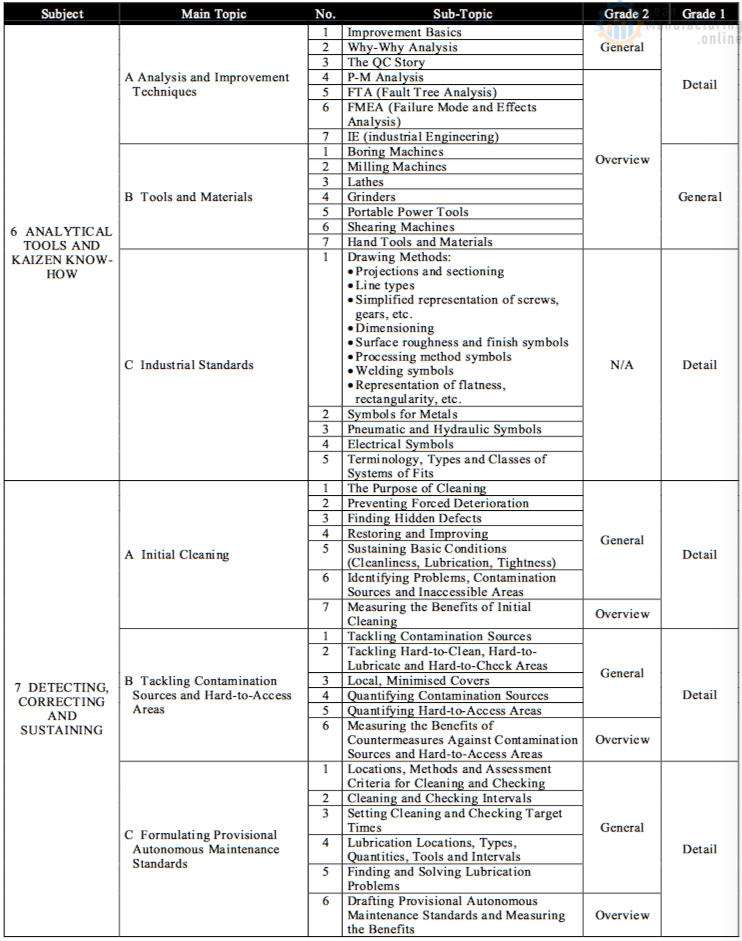

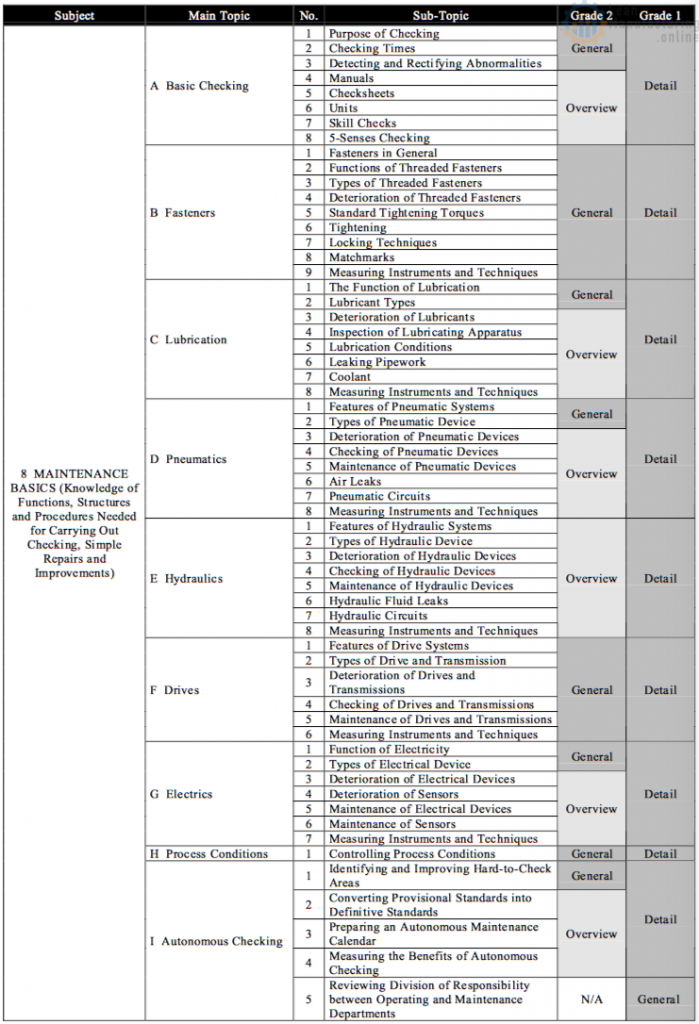

Autonomous Maintenance Practitioner Test Curriculum

Subjects, Main Topics and Sub-Topics of Written Examination

Table 9.6 Autonomous Maintenance Practitioner Test Curriculum

Key:

N/A – not applicable

Overview – outline knowledge (true/false) General – general knowledge (4-choice)

Detail – detailed knowledge (fill in the blanks)

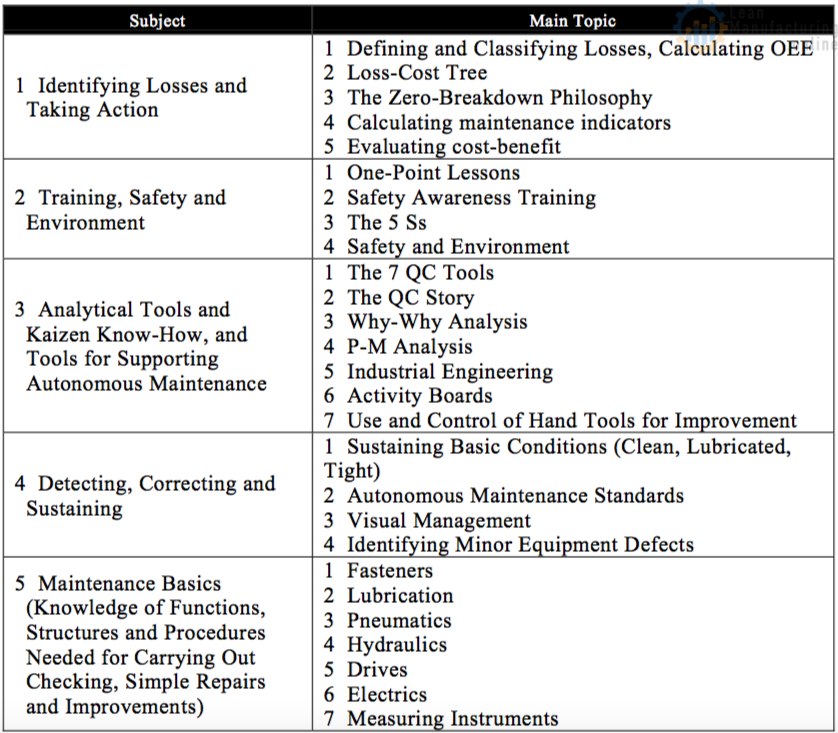

Subjects and Main Topics of Practical Examination

4. Important considerations regarding training

4.1 Conducting In-House Skills Training

4.1.1 Developing in-house instructors

(1) Setting the curriculum

The first thing to do is to establish the curriculum by looking at the equipment the company possesses and deciding on the level of skill the trainees will need, what should be taught, and how long should be spent teaching it.

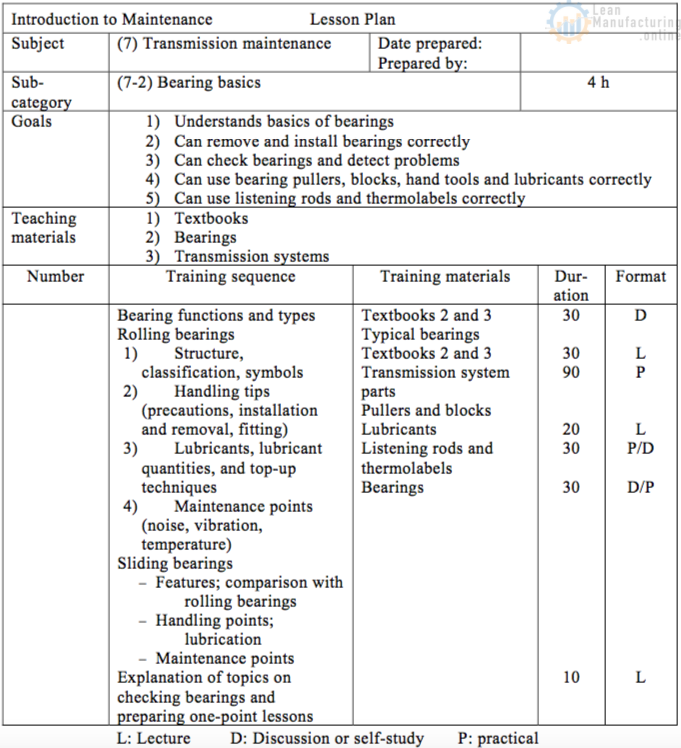

(2) Preparing lesson plans

1 If training is to be effective, the trainees must be made to study the material for themselves until they have mastered it.

2 Highly practical lesson plans tailored to the company’s particular requirements should be prepared for each item to be taught.

3 The most important thing is to prepare in-house textbooks that will permit self-study

4 Prepare practical training materials (see photographs on Page 9-14), cut-away models, etc. It is particularly important to prepare sufficient materials for each person to be able to perform the practical training individually. Expensive equipment such as transmissions, lubrication systems and control devices can be shared between 2-3 trainees.

5 A permanent skill training centre should be provided.

6 Classrooms should also be set up.

It is important for the training to be carried out on a one-to-one basis, with 6-10 trainees per class being the best number. An environment conducive to study, with space to accommodate training rigs, should be arranged.

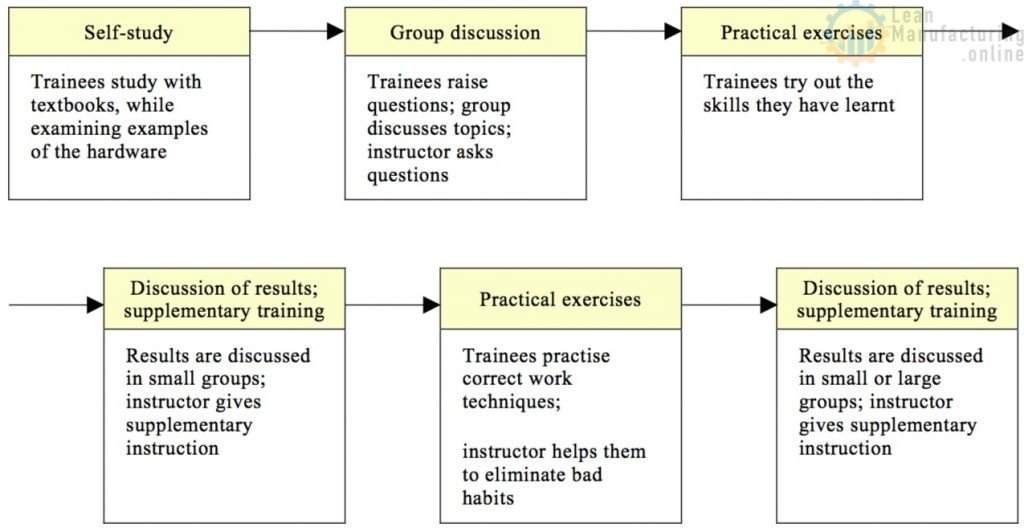

When developing skilled people able to handle sophisticated equipment, the important thing is not so much to teach them but rather to provide an environment that motivates them to learn for themselves (see Figures 9.10 and 9.11).

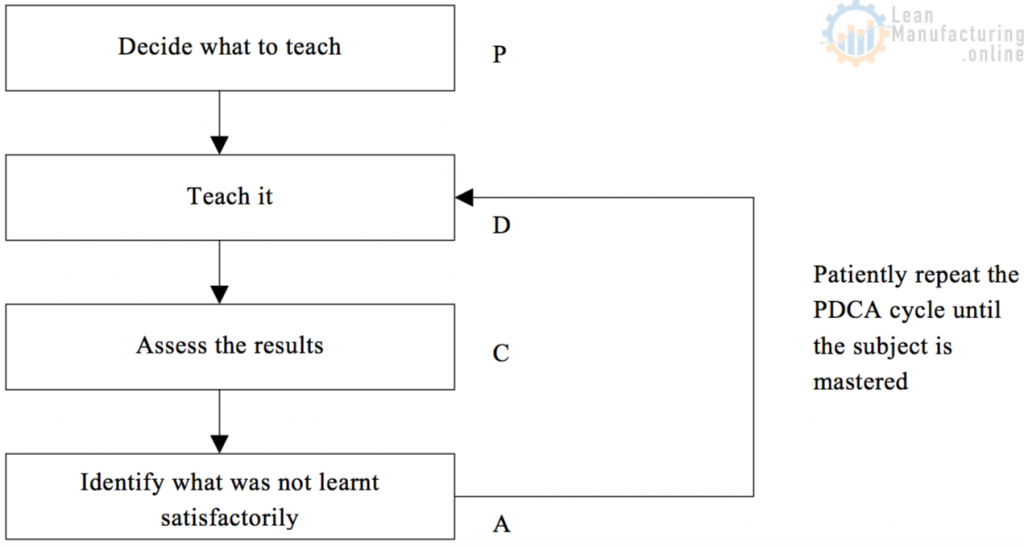

Figure 9.10 Pattern for Self-Study

Figure 9.11 Layout for Training

Figure 9.12 A Theory of Motivation

Figure 9.13 What is Teaching?