The word “Breakdown” seems to be self-explanatory. Webster’s definition of a breakdown is:“ A failure to function, a function loss, failure to progress or have an effect”.

When we apply it to equipment or assets, then anytime the equipment or asset fails to perform when required at design capacity and satisfactory quality it is broken, regardless of the root cause of the failure. This is a change from the traditional maintenance definition of a breakdown because it now implies that there can be many different types and sources of breakdowns. Not always the source of the breakdown is mechanical or electrical (traditionally considered Maintenance) in nature or easily seen; In fact, the source can be quite deceiving and often the result of trivial or less significant conditions (ie. Dust, abrasion, dirt, loosening, warping, etc.) allowed to exist for a period of time leading to the actual breakdown.

To perform OEE calculations, the definition of a breakdown revolves around “losing the primary function” of the entire line, the processing unit, or the system and not necessarily an individual component. However, this definition is often not enough for troubleshooting electrical and mechanical type of problem or sifting to find the real root cause of failures for eradication.

Maintenance requires more detailed information. This information is better placed by the Maintenance planner and expert mechanics and then entered as part of the work order in the CMMS. Later, reports/graphical representations can be obtained from the CMMS for analysis and grouping.

Is not as important to find “the correct/perfect” definition of a breakdown as it is to track the breakdowns consistently and in a simple repetitive way and being able to show a reduction of occurrences.

Therefore, a recommendation is for Maintenance to have its own definition and be the formal assignee to track Breakdowns > 10 minutes. Track OEE breakdown losses separately. In the long run, both ways are necessary and they will overlap due to the continuous improvement methodology of TPM. Meaning a reduction in Breakdowns will lead to an increase in OEE percent.

The unexpected stoppage of a equipment where a part is required or a repair over 10 min is required to restore machine functionality.

- Examples (Breakdowns):

- Seized cam replaced (25 min);

- Suction cup replaced (5 min);

- Broken cylinder replaced (35 min)

- Examples (Non-Breakdowns):

- Guide rail adjusted (10 min)

- Knife jam cleared (15 min)

- Calibrate metal detector (5 min)

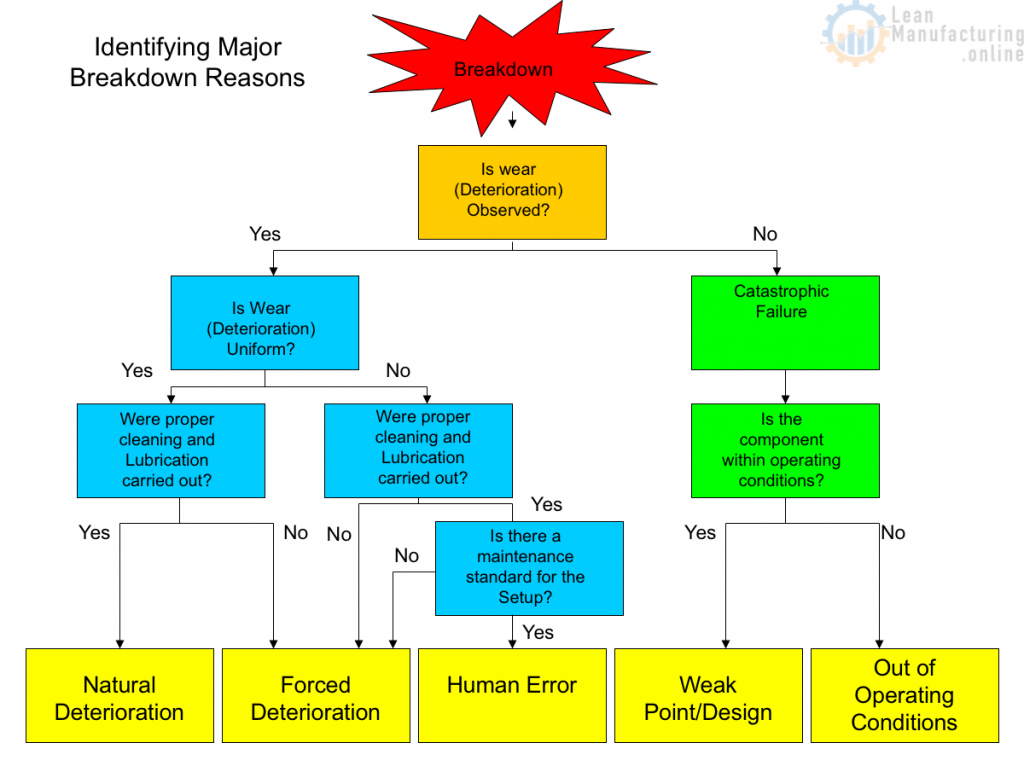

Reasons for Breakdowns

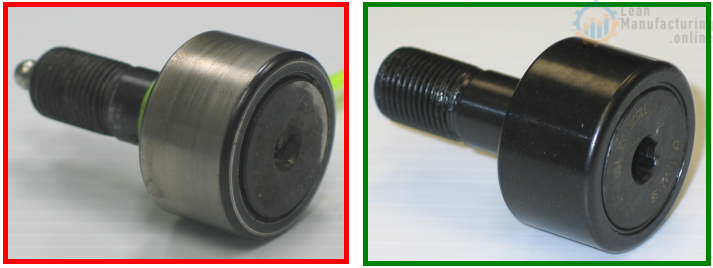

Breakdowns due to Forced Deterioration:

- A breakdown that occurs on any machine component/part due to lack of cleaning, inspection, and lubrication

- Example: A cam follower that does not wear out evenly on its contact surface

Breakdowns due to Natural Deterioration:

- A breakdown occurs on any machine component/part even though we are cleaning, lubricating, or inspecting the machine properly.

- Example: a cam follower that wears out evenly on all the contact surfaces but is no longer capable to perform its function.

Breakdowns due to Out-of-Operating Conditions:

- A breakdown that occurs on any machine component/part due to the component/part being operated beyond its intended limits.

- Example: burnt glue particles clogging the filter or nozzle on the glue system due to operating the glue pot/hose at higher temperatures than the standard.

Breakdowns due to Lack of Knowledge:

- A breakdown that occurs on any machine component/part due to improper installation or repairs.

- Example: a chipped knife blade due to improper alignment of the stationary and moving knives during setup

Breakdowns due to Weak-point Part:

- A breakdown that occurs on any machine component/part due to poor design and/or fabrication on the manufacturer’s part.

- Example: suction cup was breaking too often, reason – a wall of the suction cup too thin and weak to support the load

Breakdowns & F-Tags

F-Tagging = Cleaning is Inspection: this activity is the heart of AM Step 1 activities.

It has one main objective:

Reduce breakdowns due to forced deterioration.

And two main activities:

- Identify abnormalities (through training by mechanics), and

- Fix abnormalities (through the F-Tag process)