A program to reduce the number of steps needed to do a job and make the work area cleaner so that it is safer and more productive. The 5 steps of 5S are:

- Sort

- Set

- Shine

- Standardize

- Sustain

Rules of 5S:

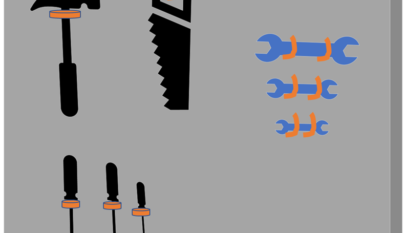

- Everything HAS a place and everything IN its place.

- Nothing on the Floor except legs, wheels, or pallets.

- When in doubt, throw it out.

What is the most disorganized area of your home?

Garage?

Garage?- Storage Closet?

- Toolshed?

Is this what your tool shed looks like?

What is the most organized place you can think of?

An example of a perfectly organized place is aisles in the grocery store.

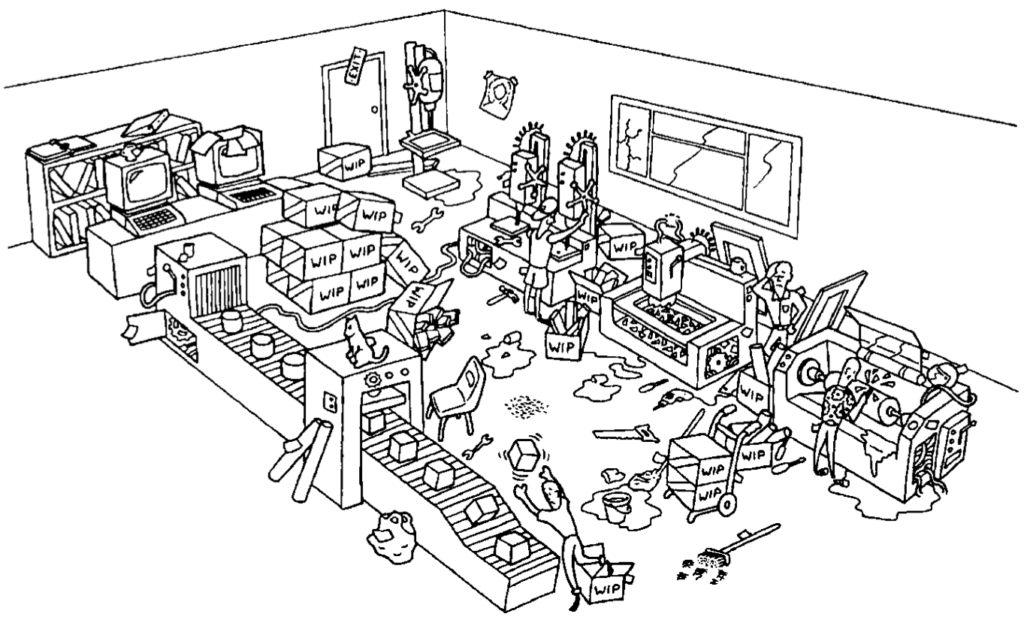

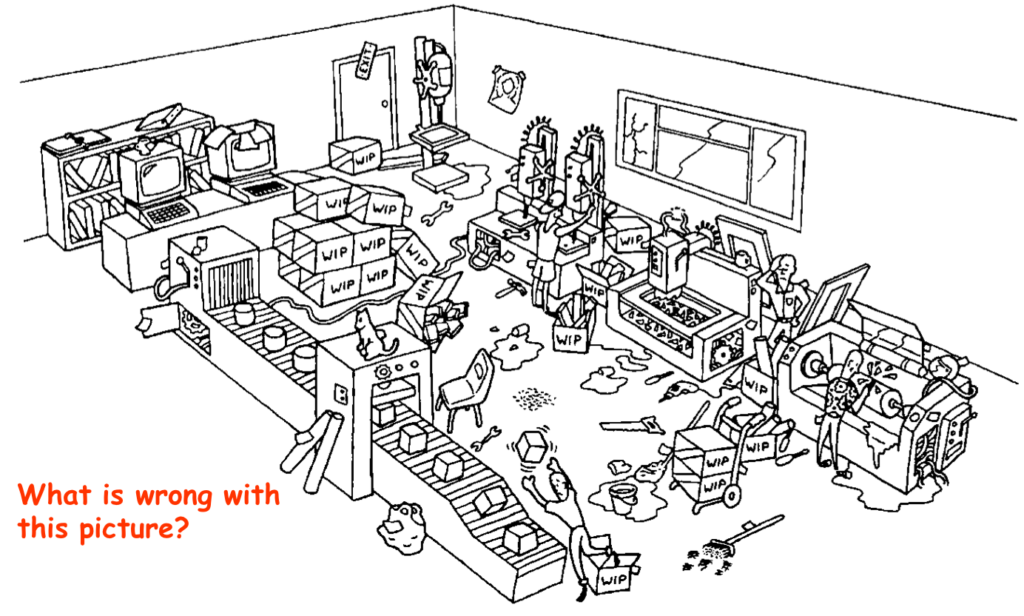

Environment Before 5S

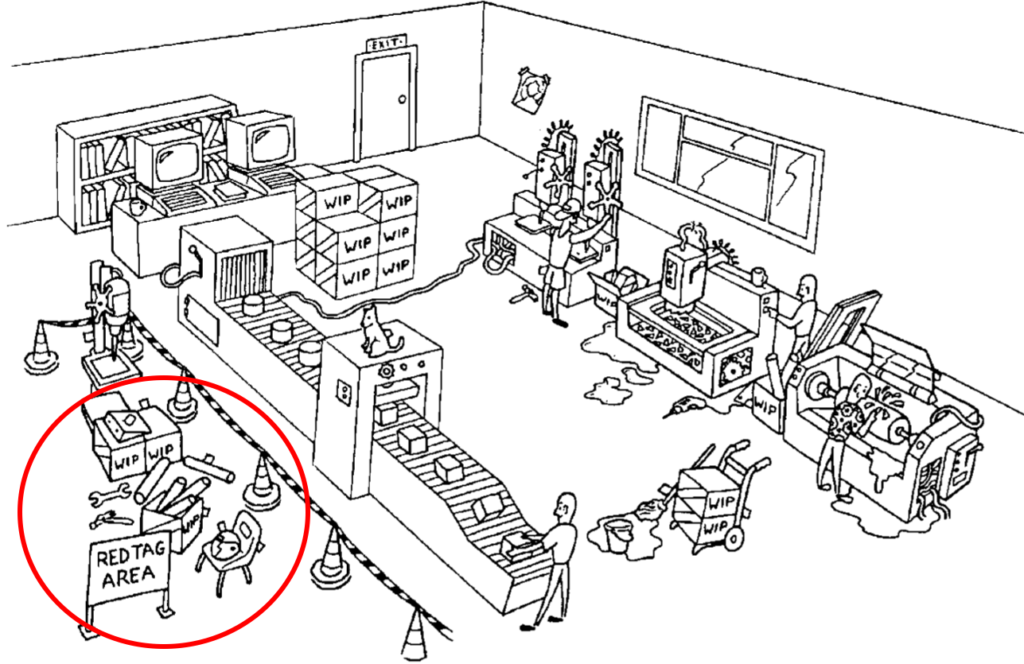

AM Step 1 Flow – Sort

- Perform the SORT activity of 5S

- Create the “Red Tag Zone” for items you do not need

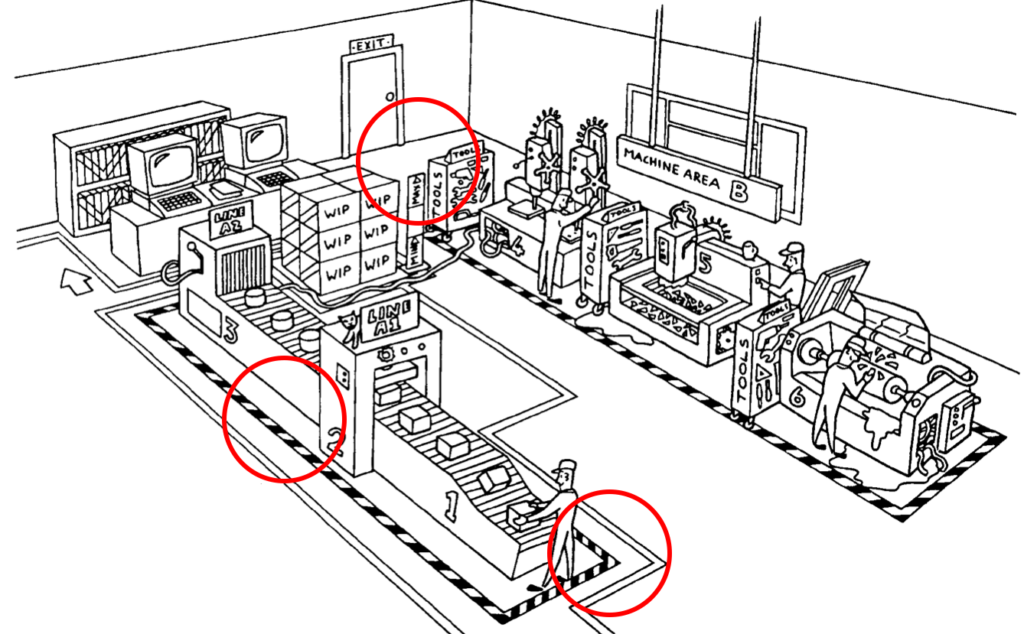

SET/STORE

- Locate a specific place for each item (tools, equipment, material), close to where it is needed

- “A place for everything and everything in its place.”

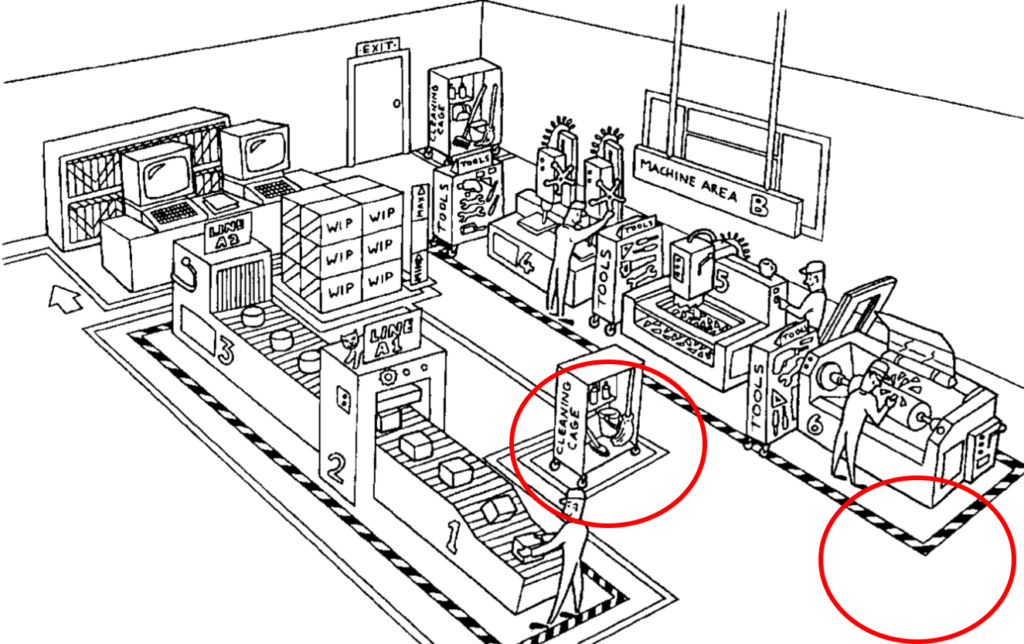

SHINE

- This is done by dividing the work area into zones and assigning roles each person is to play in their area of responsibility

- Not a simple wipe off of dust

- Eliminate sources of contamination

Standardize & Sustain

- Standardization: Create OPLs, implement demarcation

- Sustain: Self-discipline is required. Everybody is responsible for making 5 S work

Summary

- The 5S is a technique to keep the workplace organized at all times

- The 5S are Sort, Set, Shine, Standardize & Sustain

- Normally in Step 1, we only do the first three steps of 5S (SORT, SET/STORE & SHINE)

Remember the Before Shot?