December 27, 2025

0 1,691

How to Improve Manufacturing Processes with the RIVET Method

Artificial Intelligence

Continuous Improvement

Lean

Lean Manufacturing

Lean Six Sigma

Productivity

Safety

TPM

World Class Manufacturing

November 19, 2025

0 1,988

Gemba Walk GPT: The Smartest Way to Turn Observations Into Real Improvement

November 16, 2025

0 2,263

How to Create a Step-by-Step Reveal Animation in PowerPoint

Book reviews

Continuous Improvement

Leadership and Continuous Improvement

Lean Manufacturing

Lean Six Sigma

October 4, 2025

0 3,689

Explore the Best Free Online Libraries in 2025

October 3, 2025

0 3,550

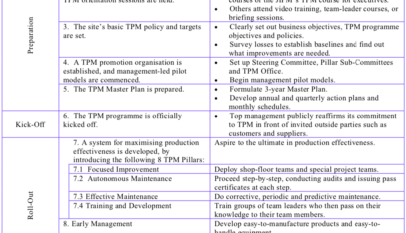

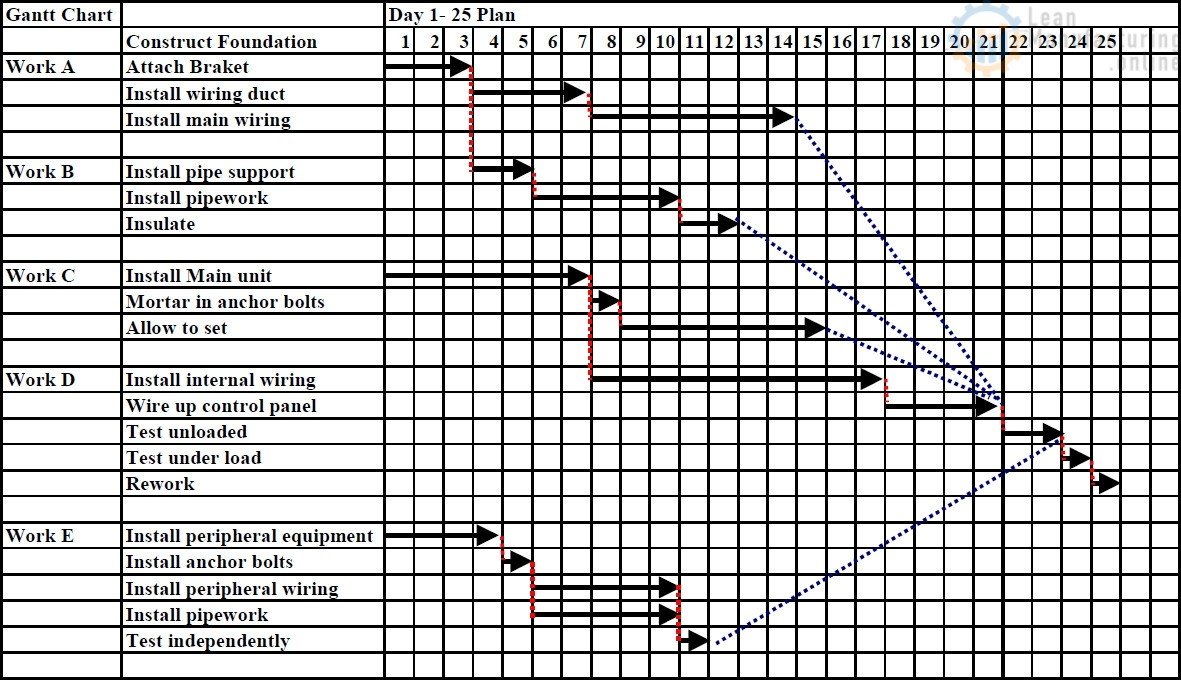

TPM Master Plan: The Roadmap to World-Class Manufacturing

December 17, 2021

1 10,255

Getting Ready for TPM

September 15, 2021

0 5,518

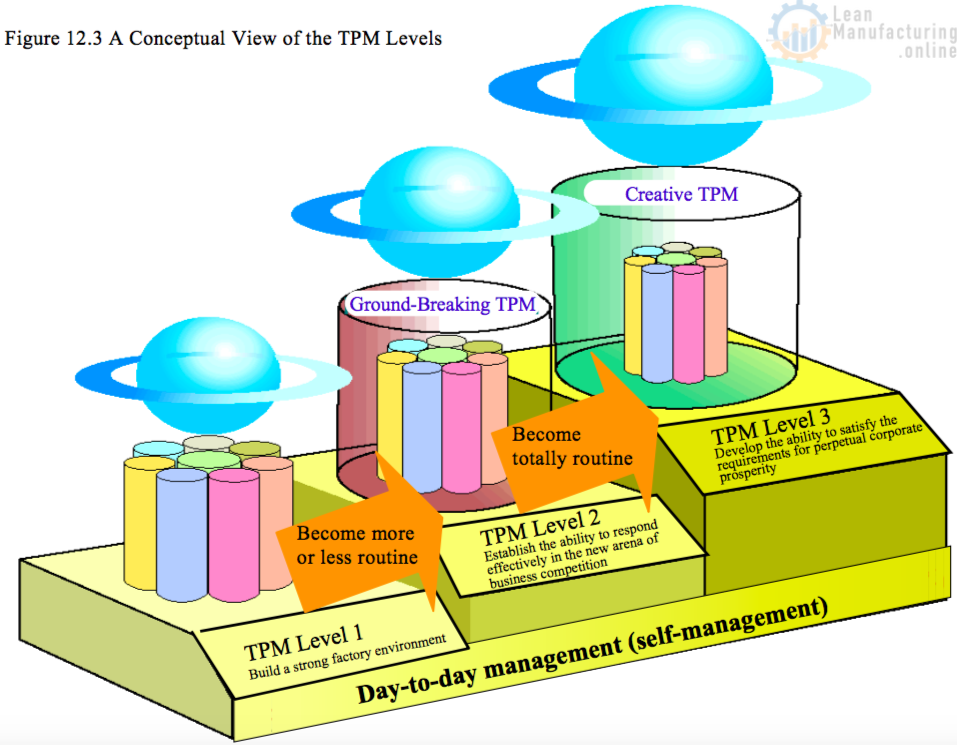

Chapter 12. Completing and Upgrading the TPM Programme (Levels 1, 2 and 3). Part 1

5S

Autonomous Maintenance

Blog

Change Management

Early Equipment Management

Early Product Management

Education and Training

Focused Improvement

Instructor Training

Manufacturing Support

Planned Maintenance

Quality

Safety, Health and Environment

TPM

TPM Introduction

World Class Manufacturing

April 30, 2021

0 22,405

TPM 3 Levels – path to World-Class Manufacturing

December 1, 2020

0 3,267

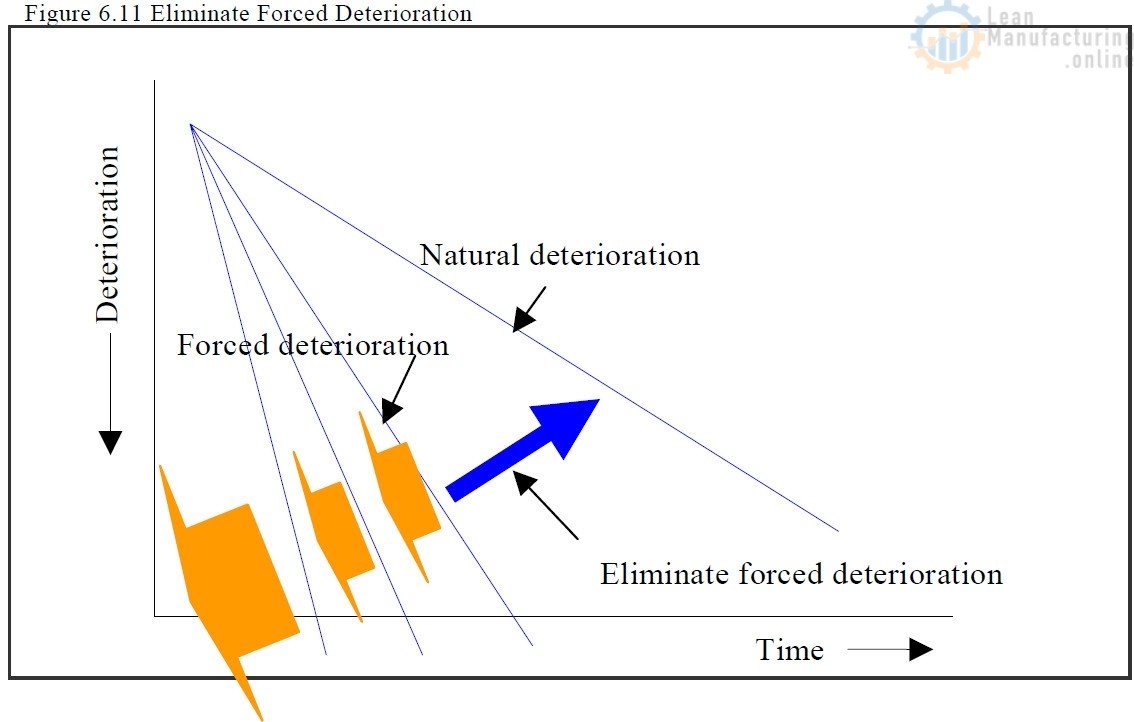

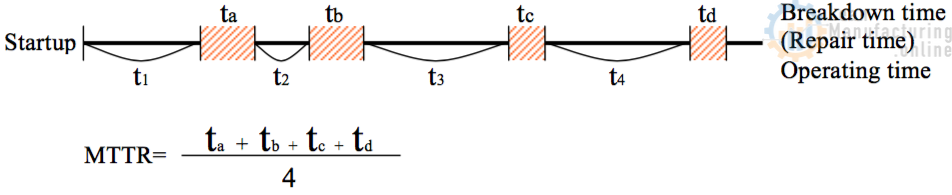

Chapter 6. Planned (Effective) Maintenance. Part 3

December 1, 2020

0 2,864

Chapter 6. Planned (Effective) Maintenance. Part 2

December 1, 2020

0 7,515

Chapter 6. Planned (Effective) Maintenance. Part 1

Most Popular

4M Analysis Process

The purpose of this procedure is to define the steps to do a 4M …

Very interesting article. I want to know who developed the methodology of Figure of 8? I heard that the concept was created for a Japanese Engineer named Kimura. Can you help me with this question?

Thanks for your question. Methodology was developed by Japanese Institute of Planned Maintenance (JIPM), Yoshifumi Kimura was one of the authors, he also developed the TPM program at Nachi-Fujikoshi. Hope this will help with your research.