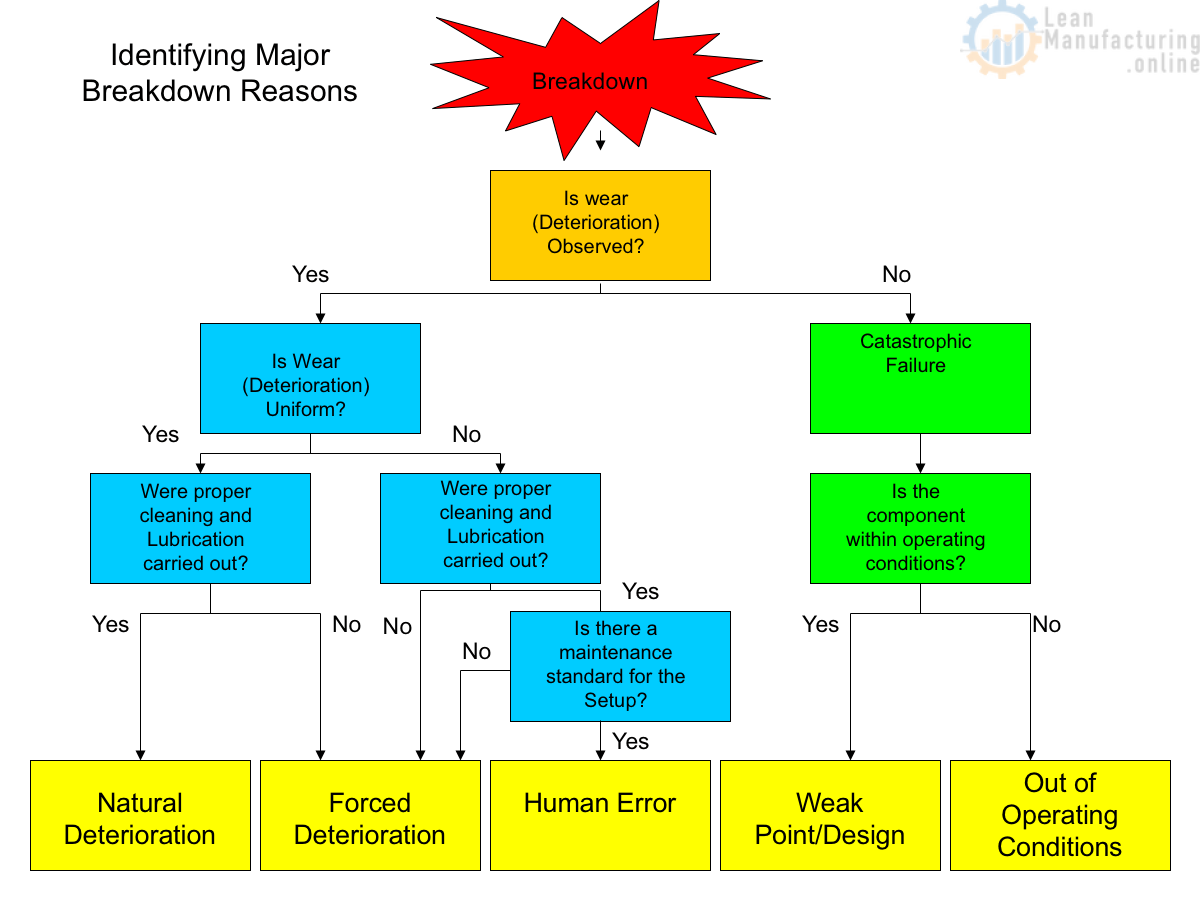

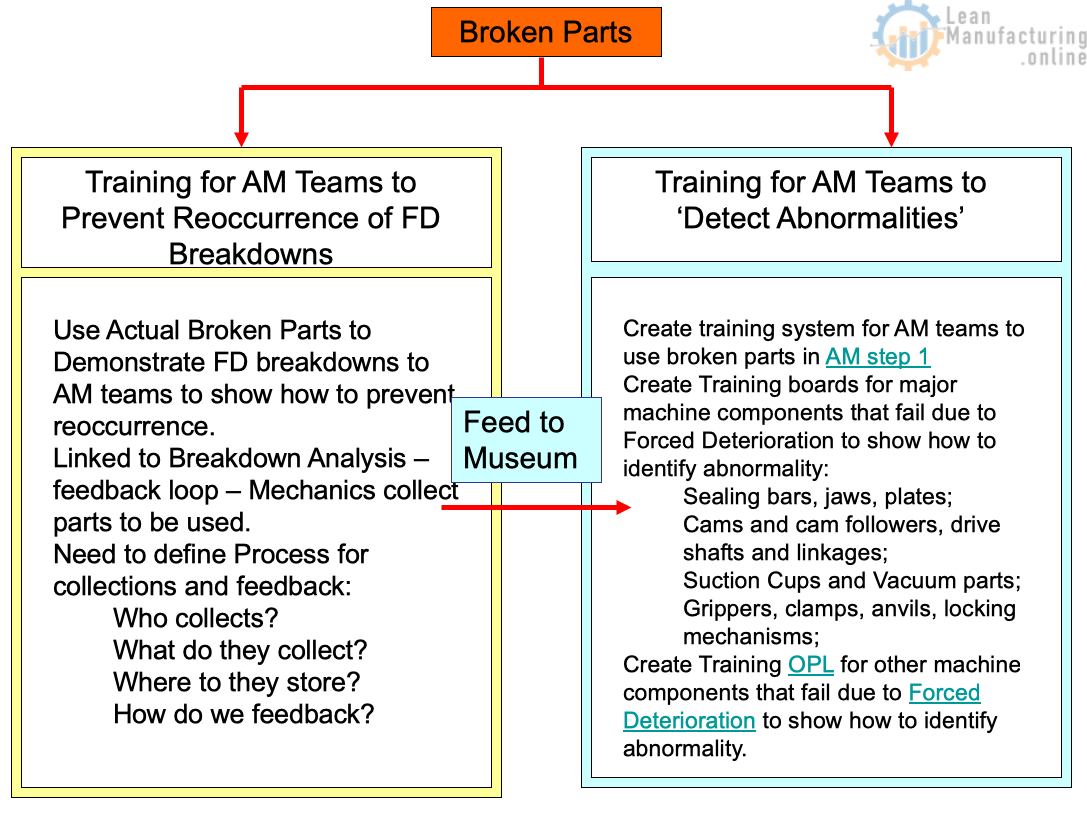

Collecting broken or worn machine parts for later analysis will help to understand root cause of failures, as well as can assist with training AM team members.

Training for AM Teams to Prevent Reoccurrence of Forced Deterioration Breakdowns

- Use Actual Broken Parts to Demonstrate FD breakdowns to AM teams to show how to prevent reoccurrence.

- Linked to Breakdown Analysis – feedback loop – Mechanics collect parts to be used.

- Need to define Process for collections and feedback:

- Who collects?

- What do they collect?

- Where to they store?

- How do we feedback?

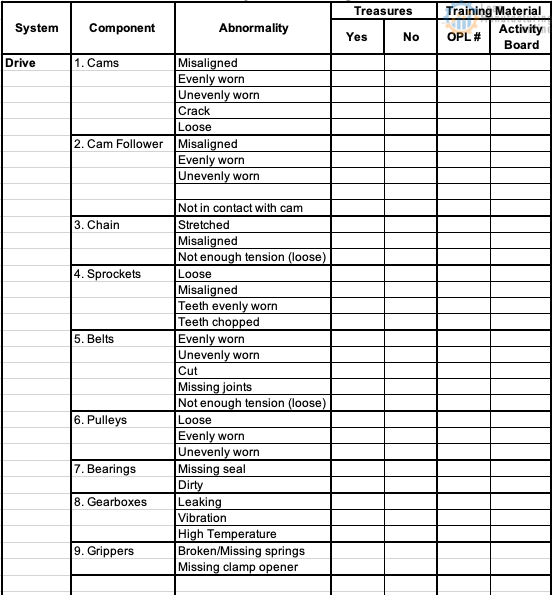

Training for AM Teams to ‘Detect Abnormalities’

- Create training system for AM teams to use broken parts in AM step 1

- Create Training boards for major machine components that fail due to Forced Deterioration to show how to identify abnormality:

- Sealing bars, jaws, plates;

- Cams and cam followers, drive shafts and linkages;

- Suction Cups and Vacuum parts;

- Grippers, clamps, anvils, locking mechanisms;

- Create Training OPL for other machine components that fail due to Forced Deterioration to show how to identify abnormality.

Abnormality Training Matrix

This is very useful information. I am also TPM Practitioner person. If you will share some images of broken Parts Musuem then it will help us to develop in our TTC, Training Room.