3. Steps in Implementing TPM-SCM

3-1 12 Steps in Implementing TPM-SCM

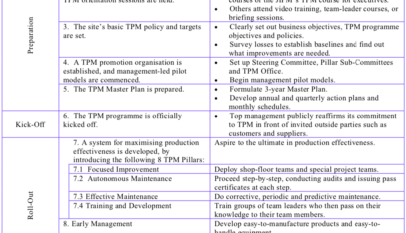

Implementation of TPM-SCM follows the “12 Steps of TPM Development,” as in TPM-MAKE. In this case, however, the content is based on the premise of company-wide development, and the steps proceed in a different order, as follows:

- Step 1: President/CEO Announcement of the Decision to Implement TPM-SCM

- Step 2: Launch of TPM-SCM implementation Training and Campaign

- Step 3: Build an Organisation to Promote TPM-SCM

- Step 4: Selecting a Model Product Line to Reduce Supply Chain Losses and to Establish a Project Team

- Step 5: Identifying Total Losses in Plan-Source-Make-Deliver

- Step 6: Project Team Makes a Model Improvement of the Supply Chain Losses

- Step 7: Setting the Basic Policy and Goal of TPM-SCM

- Step 8: Create a Master Plan for TPM-SCM Deployment

- Step 9: The TPM-SCM Kick-Off

- Step 10: Company-wide Deployment in Plan-Source-Make-Deliver

- Step 11: Achieving the Goal

- Step 12: Challenging the TPM Special Award

3-2 Step 1: The President/CEO Declaration of Decision

The purpose of the declaration is to let every employee know what top management is thinking and expecting, and to prepare employees for the task they are about to undertake. Examples of when and how to make the announcement include at a board meeting, a middle management meeting or any occasion where people involved in the plan meet together. Alternatively, the announcement can be made in the company newsletter. The key point is that the announcement should be made directly by the CEO; the job should not be delegated to managers.

Since the TPM-SCM promotion office has not been established at this point, the announcement must be handled by the existing TPM promotion section in the factory and by senior personnel in the supply chain.

Step 1 is extremely important because it clearly states what the company expects from TPM-SCM. Almost every Japanese company undertaking a TPM program makes the president/CEO declaration at the beginning of the next activity level.

3-3 Step 2: TPM-SCM Implementation Training and Campaign

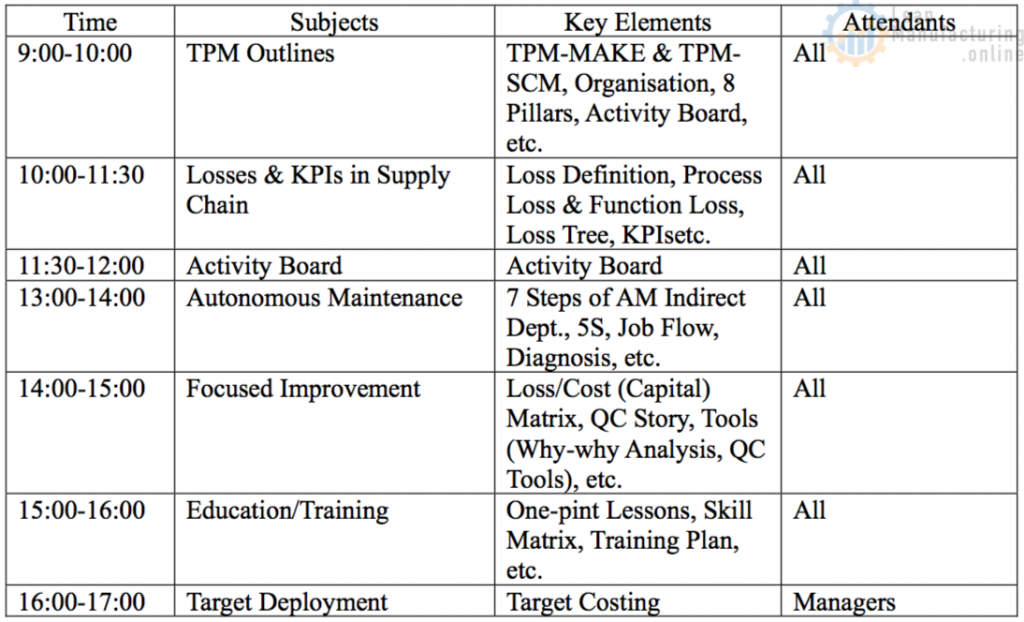

The purpose of TPM-SCM implementation training is to familiarize everyone with the TPM concept and the idea of “loss”; to ensure that everyone communicates with a common language; and to increase the motivation to challenge TPM. The training curriculum is shown in Chart 5. Training is provided for every employee. It is important that they gain a thorough understanding of basic TPM principles, especially concerning “loss” in the supply chain (details in Step 5). Unlike the Make area, staff in the Plan-Source-Deliver areas should find TPM to be an entirely new concept. It is particularly important that employees in these functions improve their perception of TPM and the concept of “loss”.

To start the training, it is recommended that companies request a one-day training program delivered by a JIPM consultant. Refer to the Chart-10 as a sample of introductory training curriculum. It is also helpful for staff in the Plan-Source-Deliver areas to go on tours of the factory and administration/indirect departments to see how those sections work with TPM, to learn from their TPM activities and to grasp what “loss” means. Such a tour could be within their own company or at another company.

Chart 10 TPM-SCM Introductory Training Curriculum

As in Step 1, the training should be discussed, planned and carried out by the existing TPM promotion group within the factory and senior personnel in the supply chain, working as a temporary promotion team.

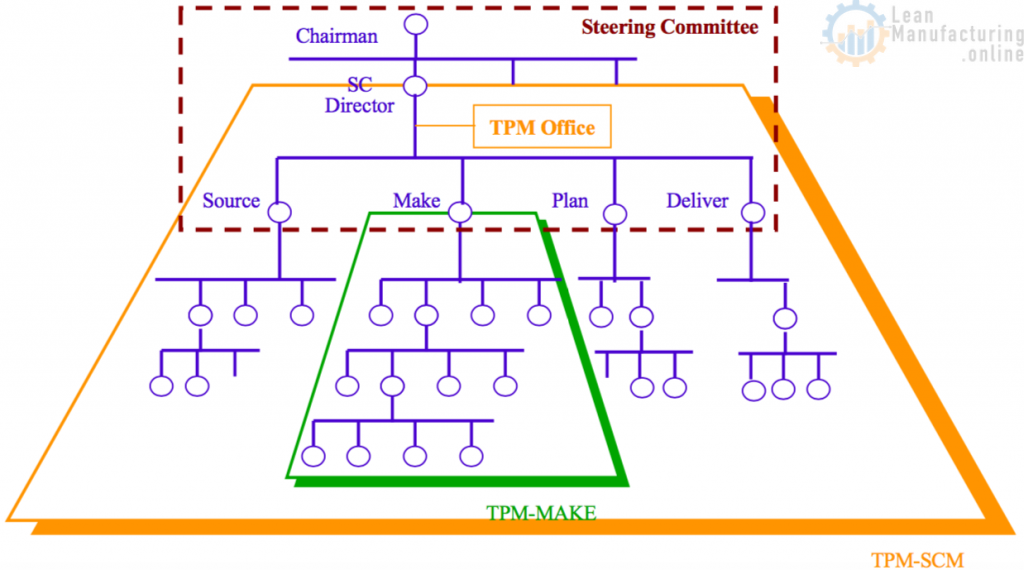

3-4 Step 3: Building An Organisation to Promote TPM-SCM

This step builds the system or organisation to promote TPM-SCM (Chart-11).

First the company must organize a TPM Steering Committee (or a TPM Promotion Committee). This group will oversee activities and delegate specific responsibilities for promoting TPM throughout the company. Members of this Committee should be department managers and ideally above director level.

It is also important that the committee should include heads of sales, R&D or other sections outside the supply chain. Even if these sections are not directly involved in TPM-SCM, it is important to try to unify the direction of TPM-SCM activities with other company/departmental policies.

Chart 11 TPM-SCM Organization

The Committee should meet monthly or bimonthly, to discuss activity progress, problems, and future plans. Some Japanese companies include these meetings in their board meeting agenda if the Committee members will all be present. The leader of the Committee must attend every meeting and try to lead the discussion.

Next, the company will organize a TPM (Promotion) Office. As the “engine” of the company’s TPM activities, this group has a very important role. In many cases in Japan the head of the Promotion Office is also a division director, but another person needs to be appointed to deal exclusively with the actual promotion work. Promotion Office should consist of exclusive members and those who already hold other titles, nominated from the supply chain, and the Office should be placed directly under the supervision of the Supply Chain Director.

At the next level are the “circles” — small groups of employees in which everyone participates. These small groups can overlap. As illustrated in Chart-11, the small groups should be organised by their job category in order to carry out their activities smoothly according to policies decided at the top level of each function. The work of the small groups is mainly directed towards improving autonomous maintenance and function losses. It is the work of the managers of each function to organise these small groups and apply for their registration with the TPM Promotion Office.

Small group activities should occupy roughly 10 hours per month, including meeting time.

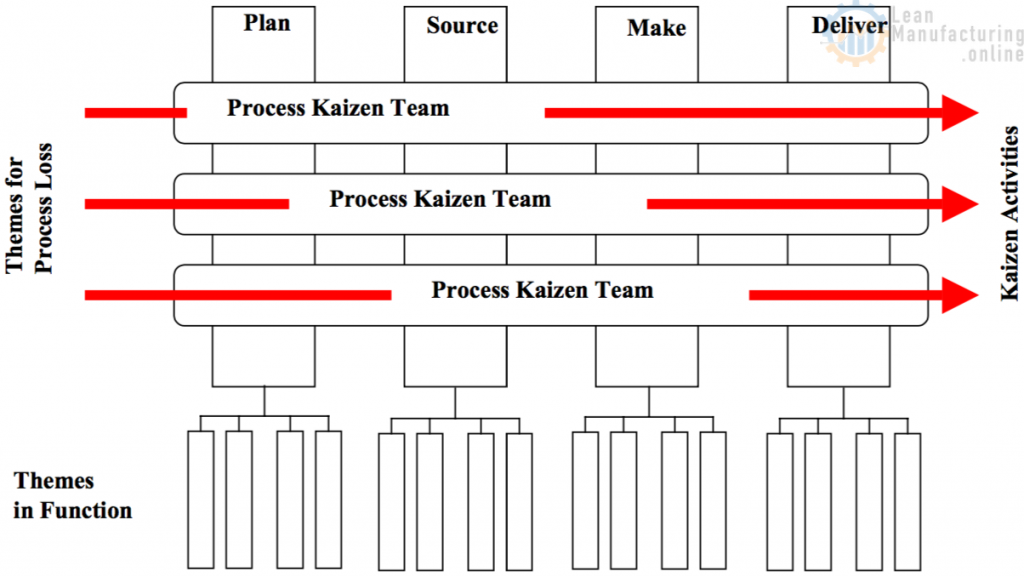

3-5 Step 4: Selecting a Model Product Line and Establishing a Project Team to Tackle to Typical Supply Chain Losses

Activities to reduce supply chain losses using a model product (“pilot” activities) are carried out under the guidance of the TPM Steering Committee. The Committee will select the model product line, assign activities to members nominated from each function who are involved in the operation of the model product line, and organize a TPM-SCM Process Loss Improvement Project Team. Team members can be non-exclusive, and should include members of the TPM Promotion Office.

While the model improvement activities can achieve loss improvements within each function (small group loss improvement), the main emphasis is on improving process losses in Plan/Source/Make/Deliver, as this will optimize overall loss reduction. The focus of the project is to reduce supply chain losses through a cross-functional effort.

Once the official kick-off takes place, members of the team will become the individuals in charge of TPM within each function.

Chart-8 illustrates a Process Loss Improvement Team. Team members are nominated after discussions between the TPM Promotion Office and the managers of each department/group.

Once decided, the team meets once every one-two week(s).

3-6 Step 5: Identifying Total Losses in Plan-Source-Make-Deliver

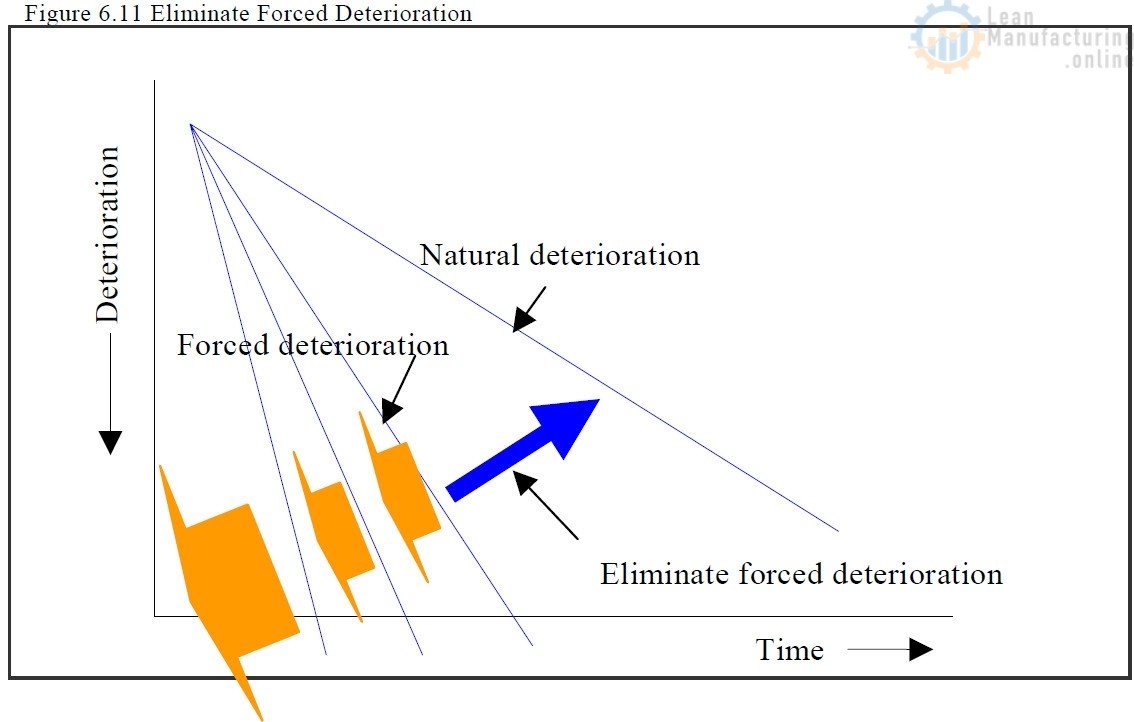

Here, the TPM-SCM pilot program team set up in Step 4 seeks to identify all the losses in the supply chain. In TPM-MAKE, a “loss” was the difference between the ideal (“to be”) state of facilities and the actual (“as is”) state, and improvements were made in breakdowns, minor stoppages, defects and the overall program for reducing Q/C/D in production. In TPM-SCM, this area expands to include losses in supply chain Q/C/D. Below are the factors for supply chain cost reduction in their correct order:

1) Target Costing.

Set strategic and innovative supply cost in order to survive and outperform the competition.

2) Set Loss Elimination Goal.

Analyze cost trends and set loss elimination goal to ensure profit.

3) Identify Total Loss within the Cost.

Design an innovative “to-be” state, and identify the difference between that and the “as is” (current) state as the total loss.

4) Execution of Improvement Activities and Progress Control.

Produce a trend graph that clearly visualizes benchmarks, goals and the reduction record.

5) Examine the Degree of Contribution to Supply Cost Reduction.

Gain understanding of potential and already visible benefits, and examine their degree of contribution to supply cost reduction.

6) Examine Record of Improved Profits

Examine cost changes and profits per quarter, semi-annual or annual closing of accounts.

The same method is also used in Step 7 of TPM-SCM, the setting of cost reduction goals based on management policy.

Loss-Cost Matrix was created to clearly identify loss contribution against the supply chain cost reduction goal set by company strategy. The same matrix is then used to provide a link to specific activity themes. Another matrix (Loss-Capital) was developed to identify the loss contribution in respect of assets. It is important to include efficiency improvements in calculating working capital (stock is a typical example).

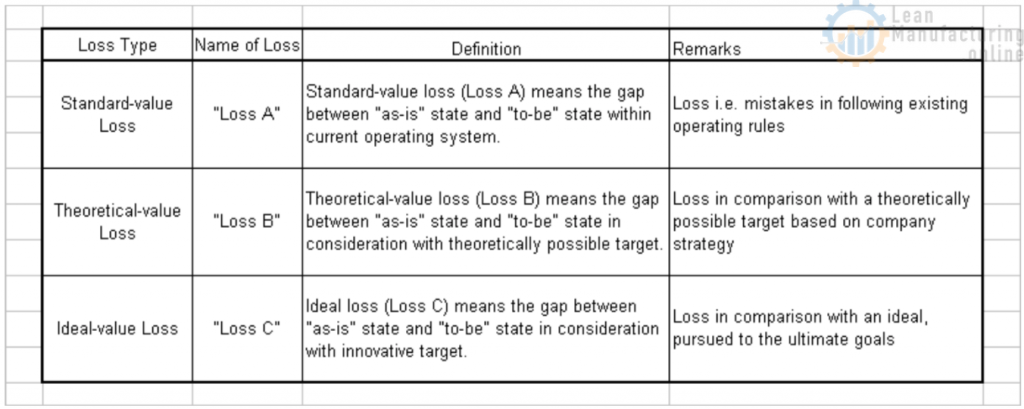

In case that the identified losses do not meet the target, it is necessary to change the way of thinking of losses. It means the level of the ideal (“to-be”) state in loss definition should be changed from “Loss A” to “Loss B” or “Loss C”, so that the gap between “as-is” and “to-be” (loss) can be expanded. The combination of “Loss A” and “Loss B” is applied to most cases in loss identification. Refer to the Chart-12 A/B/C Loss Concept.

Chart 12 Loss Definitions – A/B/C Loss Concept

In practice, the basic principles for loss identification and structuring (making loss trees) are as follows,

- Identify all the losses consistently (without missing and duplication),

- Quantify losses as much as possible,

- Allocate losses into the function where they are identified in the loss tree.

3-7 Step 6: Model Improvement against the Supply Chain Losses

For a model improvement of supply chain loss, the project team simulates numbers 4, 5 and 6 of “Order of Supply Cost Reduction”, for the loss in product line chosen in the process loss at TPM-SCM Step 4.

3-8 Step 7: Setting TPM-SCM Basic Policy and Goal

For TPM-SCM to work successfully it is as important to announce the TPM commitment in management policy or mid-range/ long-range company plans as it is to carry out practical activities. If necessary the company can:

- Use the approach outlined in Step 6 and include the TPM goal in its own annual goal,

- Build indexes of each level’s ownership of the goal, and

- Repeat execution and review.

When doing this, the company must pay attention to:

- Understanding the external environment

- Understanding the internal environment

- Understanding the environment of each department

- Understanding the work of each department

- Understanding the functions of each department

- Establishing a realistic ideal state

- Approaches to realize this state.

- Reinforcement points

- Goal

Note: An important responsibility of the TPM Steering Committee and Promotion Office is to ensure that the policy and the goal are clearly understood by the small groups in the front line.

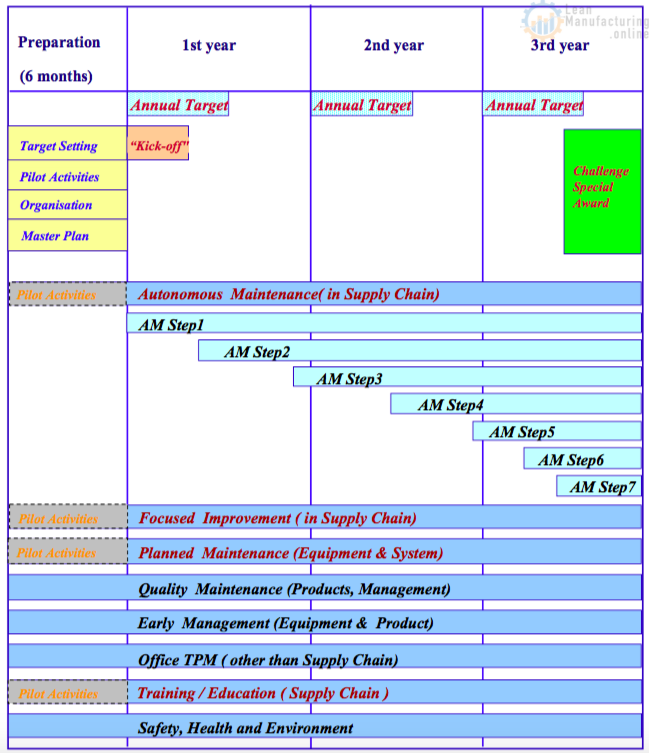

3-9 Step 8: Creating a Master Plan for TPM-SCM Deployment

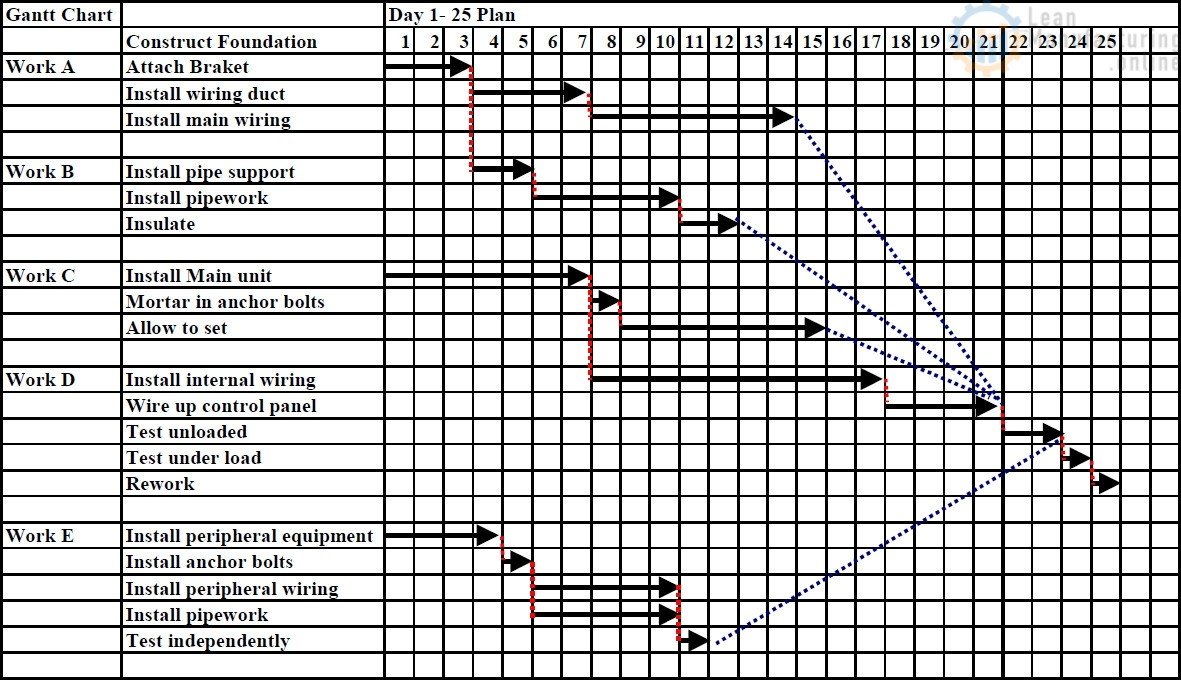

The master plan is the overall plan for obtaining the TPM Special Award. It is planned by TPM Promotion Office and approved by TPM Steering Committee. The master plan is applied from Step 9 (Kick-off) up to the JIPM review for the Special Award.

Chart-13 shows an example of a master plan of TPM-SCM.

3-10 Step 9: TPM-SCM Kick-Off

All the steps up to this point are preparatory. In Step 9 the company gathers all its employees together, and officially announces a TPM activity program to be implemented throughout the supply chain. This step marks the beginning of the challenge to eliminate supply chain loss. For success to be achieved, every employee must accept commitment to the policies set by the CEO, and must be personally involved in pushing the TPM-SCM activities forward.

Normally, a kick-off ceremony includes:

- Announcement of commitment by the CEO.

- Announcement of the objectives of setting up the TPM TPM Steering Committee, with a comment from one of the members.

- Announcement of the objectives of setting up the TPM Promotion Office, with a comment from one of the members.

- Explanation of the basic policy of TPM.

- Explanation of the goal.

- Explanation of the master plan for TPM development.

- Explanation of the results achieved by model improvement.

- Declaration by a representative of the employees.

- Encouragement from various guests. (Some companies invite customers, affiliated companies and partners to be guests at the ceremony.)

Points to remember before kick-off are:

a) Every employee must have completed implementation training before the kick-off.

b) CEO must attend the kick-off ceremony.

3-11 Step 10: Company-wide Implementation in Plan-Source-Make-Deliver

In this step, actual deployment begins across all areas of the supply chain (Plan-Source-Make-Deliver). The primary activities are conducted under 4 main pillars: Autonomous Maintenance, Focused Improvement, Planned Maintenance, and Training/Education.

The objectives of each activity pillar and their application are described below.

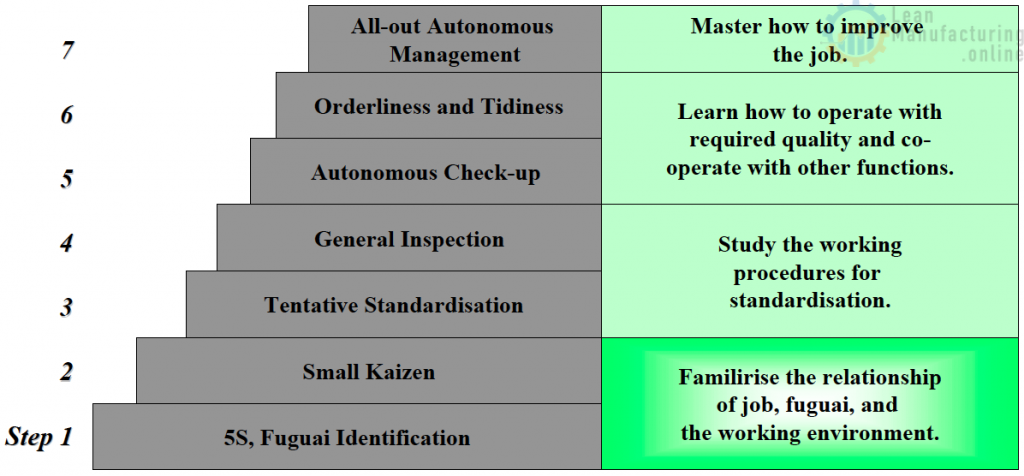

3-11-1 Autonomous Maintenance Activity

The purpose of Autonomous Maintenance activities is to improve employee competence, work efficiency and quality by gaining better awareness, developing motivation, and thus improving the overall system and work environment.

In the Make area, where the work is actual production, Autonomous Maintenance focuses on identifying defects in the facility and improving them through cleaning and inspection activities. In the Plan, Source and Deliver fields, the work is mostly indirect — administrative and creative. For this reason, most of the problems which arise are due to staff being too busy handling daily administration to devote sufficient time to the creative undertakings which build greater added value. The first imperative, therefore, is to ensure that administrative work is performed efficiently and without error. Once this is achieved, more attention can be shifted to creative work which adds value and thus improves workforce contribution to the company’s business.

Autonomous Maintenance in the Plan, Source and Deliver areas focuses on daily operations and the environment in which they take place. Operations must be made “visible” by drawing up a job flow (“Roll-paper” or “Makigami”), from which hidden defects can be identified and the process of improvement can begin. As in “Make”, there are specific steps to be followed.

- Step 1: Compile an “inventory” of the whole operation (seeking defects within the activities of the section, and the section itself).

- Step 2: Introduce small improvements (measured against defects).

- Step 3: Develop a sample of standard process (standardization of procedures, rules)

- Step 4: Undertake comprehensive inspection (learn the skills required to comply with the standard and develop the habit of frequently checking the flow chart to enable “Visual Management”).

- Step 5: Autonomous Maintenance (ongoing improvement of operation efficiency and maintenance/control.)

- Step 6: Standardization (Make operating manuals, build system)

- Step 7: Comprehensive Autonomous Maintenance (Habitual “Visual Management” and further improvements in operation efficiency on the employees’ own initiative.)

To check the completion of each step, the company should carry out self-diagnosis and top management diagnosis.

The key point to remember about activities in administrative/indirect departments (as opposed to production facilities) is that the defects which occur there are often invisible. Improvement, maintenance and control therefore depend on making them visible.

For instance, workers need to be able to sense any small problem, any deviation from the daily norm, and then take appropriate action. However, the chances of such small problems occurring is relatively low (only a few percent), so if a worker is over-zealous in their detection, efficiency in his/her other work may be compromised. A system must be developed to detect problems and recognize which ones deserve classification as defects.

“Visual Management”

“Visual Management” is a type of management tool in which the current situation is grasped visually, at a glance. Recognition through vision is very effective: studies have shown that 60% of all human activity is initiated as a consequence of visual recognition. In Autonomous Maintenance, problems are first identified, and then visualized to recognize what their control points (weak spots) are. This is how full control is achieved.

Key elements of “Visual Management” include:

- Where are the control points (weak spots)?

- When does it become a problem?

- What are the criteria to classify it as a problem?

- Can it be quantified?

- What tools are used for confirmation?

- How can confirmation be made clear and easy?

- What are the temporary measures, permanent improvements and how will they be maintained?

In facility management, visible instruments of identification include refuel marks, color-coded pipes, marks on bolts, clamp torques and so on. The same principle can be applied to administrative/indirect sections. It is important to keep the following characteristics in mind when developing ways of making the work environment easier to control.

- Easily recognized from a distance.

- Displayed on the item requiring control.

- Anyone can identify whether it is good or bad.

- Anyone can use it, and find it useful.

- Anyone can follow it, and achieve immediate improvement.

- It must make the work environment more clean/simple.

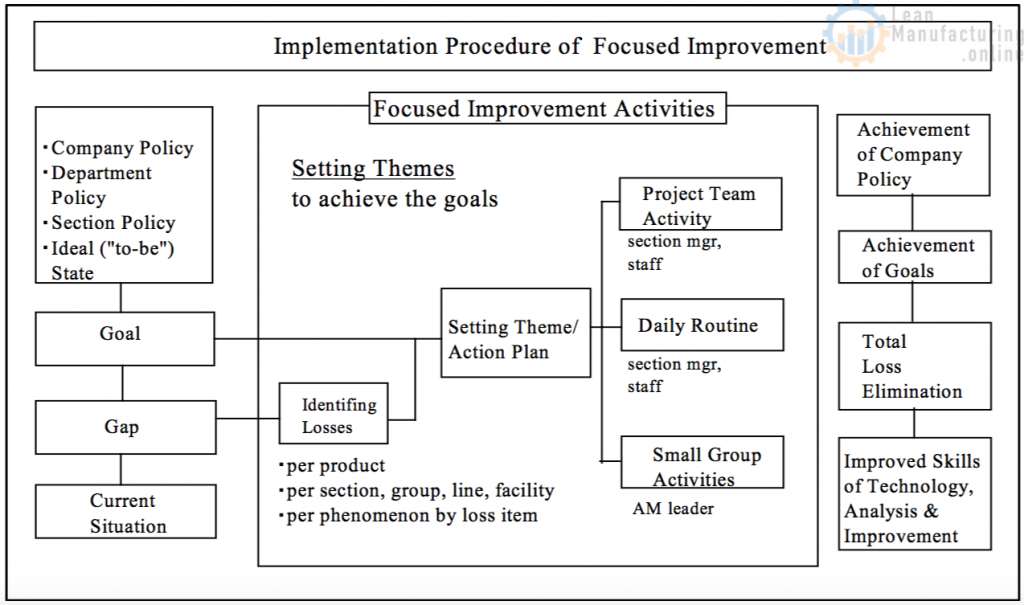

3-11-2 Focused Improvement Activity

There are many kinds of losses in Supply Chain operations (other than the 16 major losses handled in TPM-MAKE), such as stock loss, out-of-stock loss and other process losses. These need to be selected and improved, judging by strategy-based priority, degree of difficulty in elimination, and resources required.

It often happens that one loss involves a trade-off against another: the elimination of one may trigger a loss increase elsewhere. This problem is unique to the supply chain. Activities must therefore be preceded by a decision about which loss is to be reduced and by how much assessed according to its relative contribution to the business and its priority in terms of the strategy developed from target costing.

The basic principle in loss improvement is to apply equivalent effort to deciding the theme, putting priority on process losses, and improving function losses related to the theme.

Here it is very effective to use a “Loss-Cost Matrix” to clarify the relationship between target costs and losses. Similarly, a Loss-Capital Matrix can also be used.

Regarding themes: a loss that occurs in production should be handled by the production department (as in TPM-MAKE). A loss caused by a production method should be handled by the production engineering department. Maintenance department themes would include facility components whose life cycles are too short, or which require too much time for inspection and repair. Quality defects and quality cost improvements should be handled by the quality control department. Task allocation in TPM-SCM operates in the same way: the Q, C and D of raw materials are mainly handled by Source sections (procurement department); the Q, C and D of production plans and stock control by Plan sections (planning department); and the improvement of customer services by Deliver (order taking and distribution departments).

Theme selection is performed at each level — department managers, team leader, and general employees. All themes are based on top management policy and implementation begins with those whose priority is the highest. Refer to the Chart-16 Focused Improvement Procedure.

Chart 16 Procedure for Focused Improvement

In making individual improvements, the person in charge of management/control must have an accurate understanding of what is obstructing the overall optimisation. He/she must clearly grasp the concepts of total loss and of progress in Autonomous Maintenance, must select appropriate themes, and must show strong leadership in promoting activities.

For progress control against goals, there must be

- a clearly identified management performance indicators (KPIs or PIs) for at each level,

- reviews at regular intervals, and

- improvements designed to raise employee skills and work environment systems.

Focused Improvement must achieve practical results in a short period of time (usually 3 to 6 months). Themes related to process losses and function losses must be appropriately prioritised and set, and improvement activities must be conducted according to the schedule decided by the steering committee.

Because a process loss requires cross-functional activity, project team members should be selected on a cross-departmental basis. To lead the project effectively, the team leader must understand not only his own department but others as well. Managers and project leaders play a very important role in supporting successful activities.

Points to Remember in “Makigami Analysis”

a) Use actual bills and formats containing real data. Analyse the actual work and work- flow in each section.

b) Everyone involved with an operation must become a member of the team dealing with it, even if he/she has no direct responsibility.

c) The person in charge of the target operation must not conceal the truth or make excuses, but must declare the real situation based on facts. Others must not accuse him/her. The purpose here is not to apportion blame, but share responsibility.

d) Try to quantify all the types and numbers of bills/formats, all time lost to stoppage/delay, the number of steps in a work process, the level of difficulty of the tools used in that process, and the work itself.

e) When searching for problems, refer back to the goal of the work and look at it from a Q/C/D perspective.

f) Raise as many problems as possible, then sort them out by type. Remedial measures should be discussed after the problems are divided into those that can be improved immediately and those that require time for improvement.

g) Build up as many small improvements as possible.